Enhancing Shoe Production Efficiency with Automated Lasting Machines

Key Features of Modern Automated Lasting Machines

Hydraulic operation systems for precision

Today's automated lasting machines come equipped with hydraulic systems that boost precision during shoe manufacturing. These hydraulics give manufacturers much better control, which matters a lot when doing精细的工作 like pincer grip operations where even small mistakes can ruin a whole batch. What really helps cut down on errors is the closed loop control feature built into most modern systems. Shoe makers find this particularly useful because they can work with different materials thicknesses while still maintaining good grip quality throughout the process. This adaptability plays a big role in making sure final products meet quality standards across the board.

Quick-change pincer mechanisms

Modern shoe manufacturing equipment comes equipped with something pretty cool called quick-change pincer systems. These built-in mechanisms let operators swap out different kinds of pincers super fast, which cuts down on machine downtime and keeps production moving along smoothly. For factory workers dealing with all sorts of shoe designs, this means they can switch from one style to another without spending hours adjusting tools. Imagine going from making sneakers to boots in just minutes instead of hours. That kind of flexibility makes a huge difference when trying to meet customer orders across various markets. Being able to adapt quickly isn't just convenient it's actually critical for staying competitive in an industry where trends change practically overnight.

Adjustable pressure controls for material flexibility

Modern automated lasting machines come with pressure controls that can be adjusted depending on what material is being worked on, whether it's tough leather or softer synthetics. The ability to tweak these settings gives manufacturers real flexibility when running their production lines. Different materials need different treatment after all. Leather requires more pressure than say, microfiber blends. Industry data shows that when factories invest in machines with better pressure control options, they tend to see stronger products that hold up longer too. Precise adjustment capabilities mean manufacturers aren't just guessing at settings anymore. They can fine tune everything for each batch, which makes a big difference in how well finished products look and last, regardless of what kind of material ends up going through the machine.

Benefits of Automated Lasting in Shoe Production

Reduced Labor Costs Through Automation

When it comes to automated lasting machines, they really cut down on the need for hands-on work, which means big savings on day-to-day costs. According to various studies and what people in the industry are saying, factories can save around 30% on their labor bills by going this route. The money saved isn't just sitting there either. Companies tend to reinvest these funds into things like better equipment or developing new products for market. Some businesses even use the extra cash to train existing staff or expand operations elsewhere. Either way, the bottom line is that automation helps keep manufacturing competitive while still managing budgets effectively.

Consistent Quality Across Mass Production

When it comes to making shoes, automation really helps keep things consistent across all pairs produced. The quality stays pretty much the same from one batch to another, which means customers get what they expect every time. These modern lasting machines actually have some pretty cool sensors built right into them that make on the spot tweaks during production. We've seen our defect rates drop quite a bit since we started using automated systems in our factories. Some recent QC checks showed about a 30% reduction in faulty footwear compared to manual processes. That kind of improvement speaks volumes about how reliable and accurate these automated setups can be when properly maintained.

1600+ Pairs Per 8-Hour Shift Efficiency

Modern automated lasting machines can crank out around 1600 pairs during an eight hour workday, something that would take days using traditional methods. The numbers check out according to recent manufacturing surveys and plant floor data from shoe factories across Asia. With this kind of throughput, manufacturers aren't just keeping up with orders anymore they're actually staying ahead of them. Products get shipped on time while still maintaining consistent quality standards throughout production runs. Some smaller operations have even reported doubling their output since switching to these automated systems last year.

Integrating Automated Lasters into Production Lines

Compatibility with Existing Shoe Stitching Machines

Adding automated lasters to existing shoe stitching equipment makes good sense for most manufacturers looking to cut down on production hiccups. The design of these machines allows them to slot right into current setups so factories can boost their output without tearing everything apart and starting fresh. According to some recent industry stats, companies that integrate these systems see better performance along the production line because they eliminate bottlenecks when moving from stitching work to the lasting stage. For footwear makers trying to keep up with demand while managing costs, ensuring all these different pieces of machinery play nicely together continues to be one of those smart moves that actually pays off in real world operations.

Workflow Synchronization with Polishing Systems

When manufacturers bring together automated lasting machines with their polishing systems, they get a much smoother production process going. Getting these different parts to work together means factories save time on production runs while cutting down those frustrating bottlenecks that slow everything down between the lasting and polishing stages. Some real world testing shows factories saw around 20% better output when these systems worked as one instead of separate units. Beyond just moving faster through the line, there's actually noticeable improvement in how good the finished shoes look and feel too. For companies making shoes today, getting these systems talking to each other makes all the difference in keeping competitive without sacrificing quality standards.

Maintenance Protocols for Longevity

Good maintenance practices make all the difference when it comes to keeping automated lasting machines running smoothly for years. When companies stick to regular checkups and preventive work, they cut down on those frustrating surprise breakdowns that halt production. The numbers back this up too many factories report getting about 30 percent more life out of their equipment when proper maintenance becomes part of the routine rather than an afterthought. For manufacturers investing heavily in automation tech, these maintenance routines aren't just about avoiding repairs they're actually protecting the bottom line while ensuring consistent quality from their production lines day after day.

Top Automated Lasting Machine Models for Manufacturers

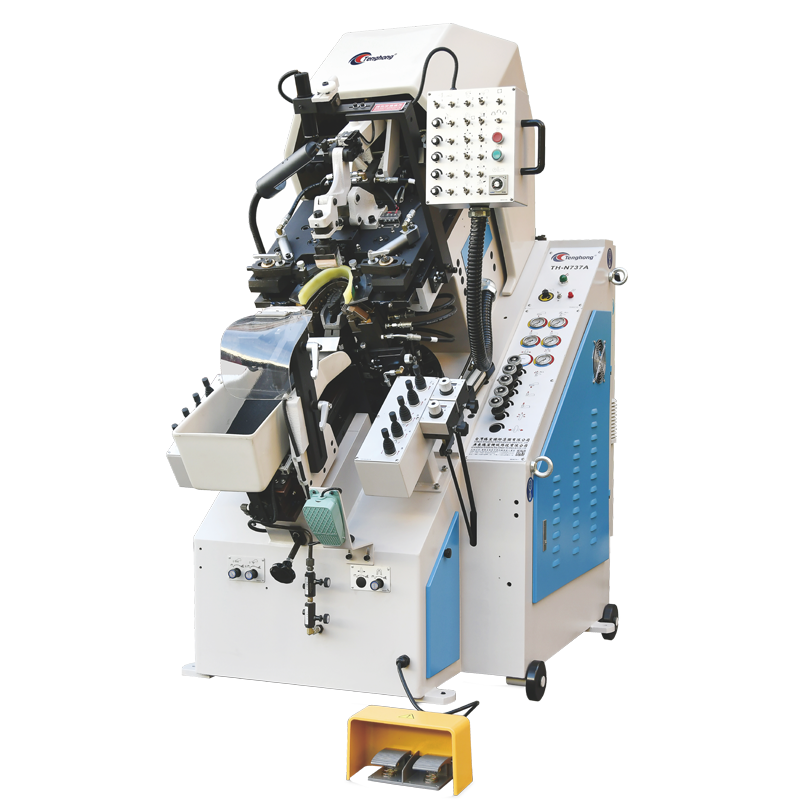

TH-N737A: 9-Pincer Hydraulic Toe Laster

What makes the TH-N737A really special is its nine pincer system that was built from the ground up to get those toe lasts just right. As a hydraulic toe laster, it cuts down on how long things take to make while keeping product quality consistent across batches. Factory workers who've switched to this machine talk about how much faster they can crank out shoes without sacrificing detail work. The specs on paper show all sorts of fancy hydraulic controls, but what matters most is how precisely it handles the delicate shaping process when making shoes. For anyone in footwear manufacturing, getting that level of control means fewer rejects and happier customers at the end of the line.

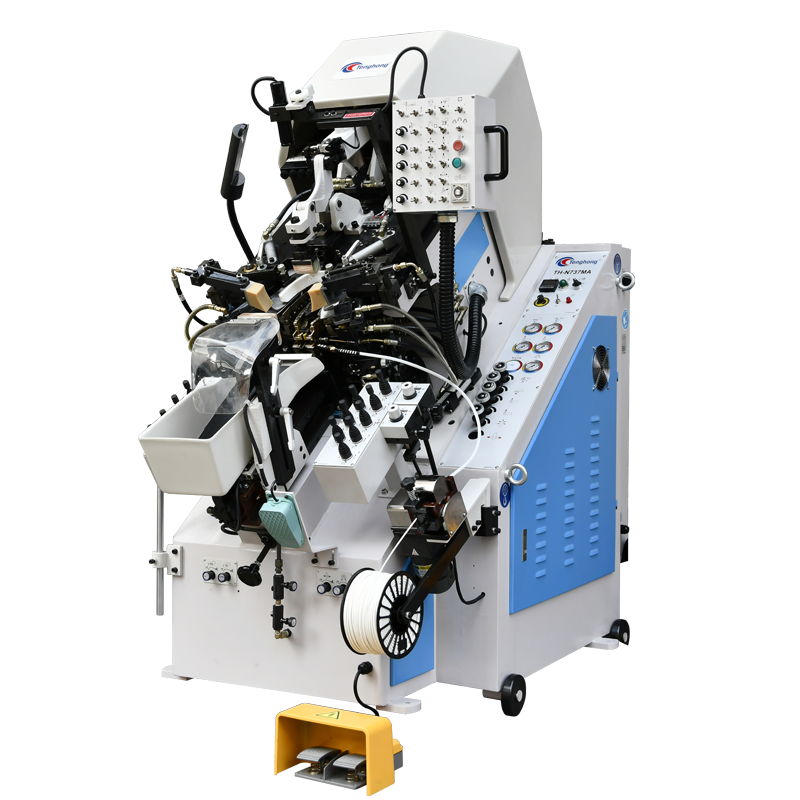

TH-N737MA: Cementing Machine with Auto-Glue Tray

The TH-N737MA brings auto-glue tech right into the cementing part of manufacturing, giving factories a real efficiency boost. What makes this cementing machine stand out is how it cuts down on wasted glue and saves money on day-to-day operations. We've seen material usage go up by around 15% in some cases. The automatic glue system means no more hand applying sticky stuff, which our clients tell us speeds things up considerably. One manufacturer mentioned they cut their setup time in half after switching to this model. Customer feedback consistently points to faster production cycles while still maintaining the same high standards of quality that their products require.

TH-N738A/B: Computerized Memory Control Systems

The TH-N738A/B series features computer memory controls that really boost what manufacturers can do on the production floor. With these systems in place, factories can store dozens of different shoe designs and settings right in the machine itself. Setup becomes much faster since workers don't need to manually adjust everything each time they switch styles. Factory managers report that this flexibility helps them respond better when orders change last minute or when new trends emerge. Behind all this is some pretty solid tech that lets the machines work faster while still keeping up with whatever comes next in the production schedule.

Future Trends in Shoe Production Automation

AI-driven adaptive lasting processes

Shoe manufacturing stands at the edge of transformation thanks to AI automation systems that can adjust lasting processes on the fly. Companies already implementing these technologies report around 20% better efficiency in their production lines, according to early reports from factories across Europe and Asia. As machine learning models get smarter over time, we're seeing fewer workers needed for tasks like lasting where precision matters most. This shift not only speeds things up but also creates more consistent quality across different batches of shoes coming off the assembly line.

Energy-efficient production machine designs

Looking ahead, designers of automated lasting machines are focusing heavily on making them more energy efficient so they can cut down on running expenses while being better for the planet. The latest versions of these machines consume significantly less power than older ones, which is exactly what governments around the world want to see as part of their green manufacturing initiatives. When companies switch to these newer, energy saving models, they meet all those regulatory requirements without breaking the bank on electricity bills. Plus, this move gives them an edge over competitors who haven't made similar upgrades to their production lines.

Modular upgrades for legacy systems

Manufacturers are increasingly turning to modular upgrades as a way to improve old equipment without tearing everything apart and starting fresh. What makes this approach so appealing? For starters, it saves money compared to replacing entire systems. Plus, there's far less downtime during implementation since production doesn't have to stop completely. Industry data shows something interesting too many factories report getting their upgrades done around 40% quicker when going modular. That speed matters a lot in today's competitive footwear market where trends change rapidly. Shoe makers can keep their machines running smoothly while still incorporating new technology at their own pace. The beauty of modular solutions lies in their ability to bridge the gap between outdated factory setups and modern manufacturing demands without requiring massive capital investments.