Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 and located in Houjie, Dongguan, is a premier shoe making machine manufacturer and a trusted B2B supplier for footwear factories worldwide. Over more than two decades, Tenghong has specialized in designing, producing, and selling high-tech, industrial-grade shoe production equipment that combines precision, durability, and automation to meet the growing demands of global footwear manufacturing.

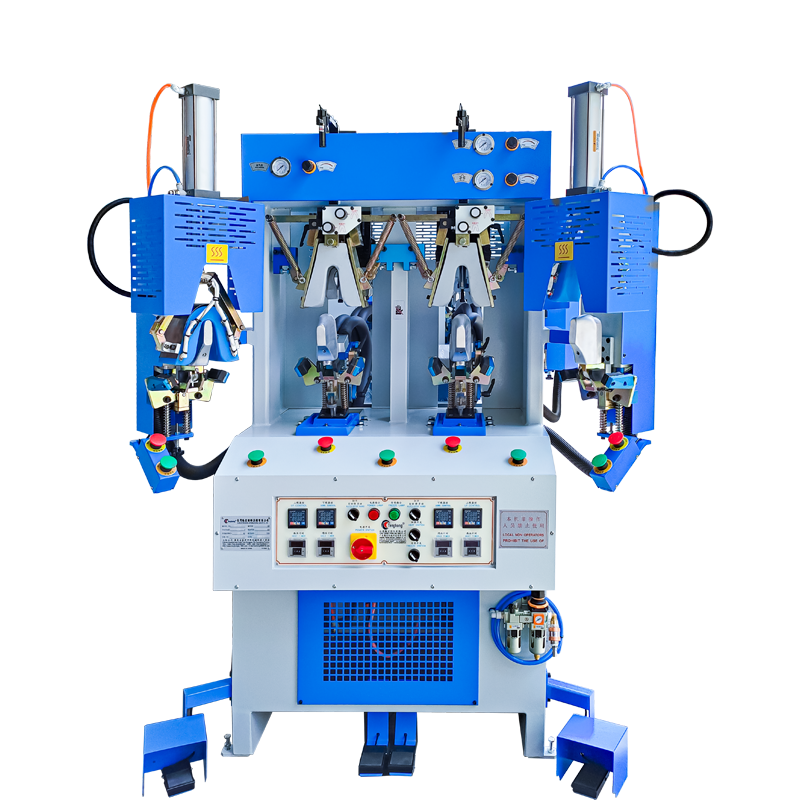

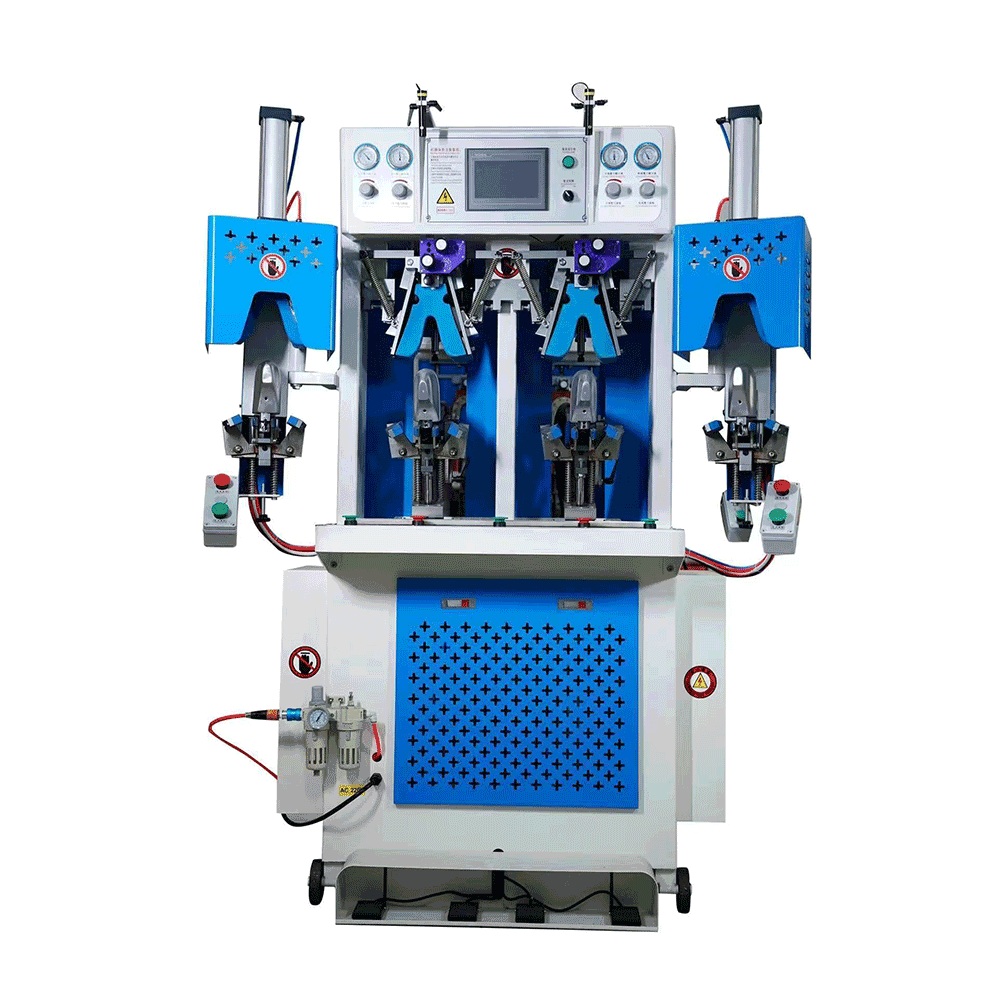

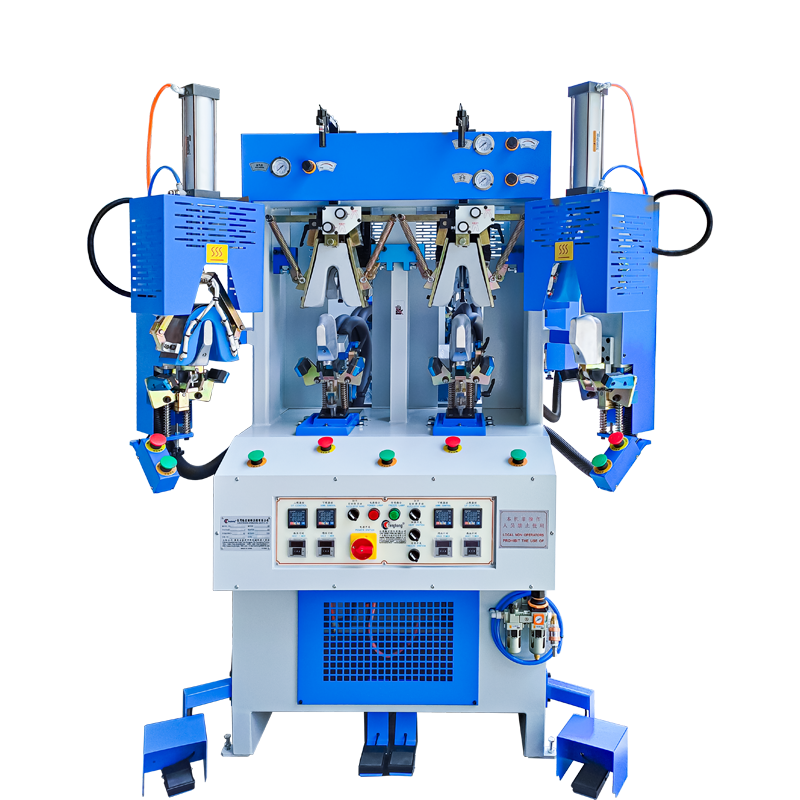

The company’s extensive product portfolio includes high-speed stitching machines, automated shoe assembly lines, vulcanizing presses, sole trimming and polishing equipment, and multi-functional combination machines suitable for leather, fabric, and synthetic footwear production. Every machine is engineered for high-precision operation, low noise, energy efficiency, and minimal material waste. Tenghong leverages modular designs, allowing manufacturers to quickly adapt molds and settings for various shoe styles, improving production flexibility and efficiency.

At the core of Tenghong’s competitive advantage is its R&D team of over 150 highly skilled engineers, technicians, and industry experts. The team continuously innovates to integrate automation, intelligent control systems, and IIoT-enabled monitoring into machinery, enabling predictive maintenance, real-time production analysis, and remote diagnostics. These innovations not only reduce operational downtime but also optimize labor allocation and overall production cost for B2B clients.

Tenghong’s machines comply with CE and ISO quality standards, reflecting rigorous manufacturing protocols and international certification, making them suitable for factories across Southeast Asia, Europe, and other global markets. The company maintains strict quality control at every stage—from raw material selection, precision component manufacturing, assembly, to final performance testing—ensuring that each machine delivered to clients performs reliably under continuous, high-intensity production conditions.