2000 সালে ডংগুয়ানে প্রতিষ্ঠিত গুয়াংডং টেংহং মেশিনারি টেকনোলজি কোং লিমিটেড হাই-টেক জুতা মেশিনারি উত্পাদনে স্বীকৃত নেতা হিসাবে প্রতিষ্ঠিত হয়েছে। দুই দশকের অধিক সময়ের দক্ষতা সহ, কোম্পানিটি জুতা এবং ব্যাগ উত্পাদনের জন্য উন্নত সরঞ্জামের সম্পূর্ণ পরিসর সরবরাহ করে। 150 জনের বেশি দক্ষ পেশাদারদের দলের সমর্থনে, টেংহং গবেষণা ও উন্নয়ন, উত্পাদন, ইনস্টলেশন এবং পরবর্তী বিক্রয় পরিষেবাগুলি একটি সহজসাধ্য ব্যবস্থায় একীভূত করে। কোম্পানির মেশিনারি আন্তর্জাতিক সিই মান পূরণ করে এবং দক্ষিণপূর্ব এশিয়া, ইউরোপ এবং অন্যান্য অঞ্চলের ক্লায়েন্টদের দ্বারা আস্থা পায়। আইএসও প্রত্যয়িত মান ব্যবস্থাপনা এবং বৈশ্বিক পরিষেবা সমর্থন সংযুক্ত করে, টেংহং গ্রাহকদের জন্য স্থিতিশীল, স্থায়ী এবং দক্ষ সমাধান নিশ্চিত করে। কোম্পানি নিরবচ্ছিন্ন নবায়নের প্রতি প্রতিশ্রুতিবদ্ধ, শুধুমাত্র কার্যকর ব্যয় কার্যকর সরঞ্জাম প্রদান করে না বরং আন্তর্জাতিক জুতা উত্পাদনকারীদের বিবর্তিত প্রয়োজনীয়তা মোকাবেলা করে এমন কাস্টমাইজড প্রযুক্তিগত সমাধানও প্রদান করে।

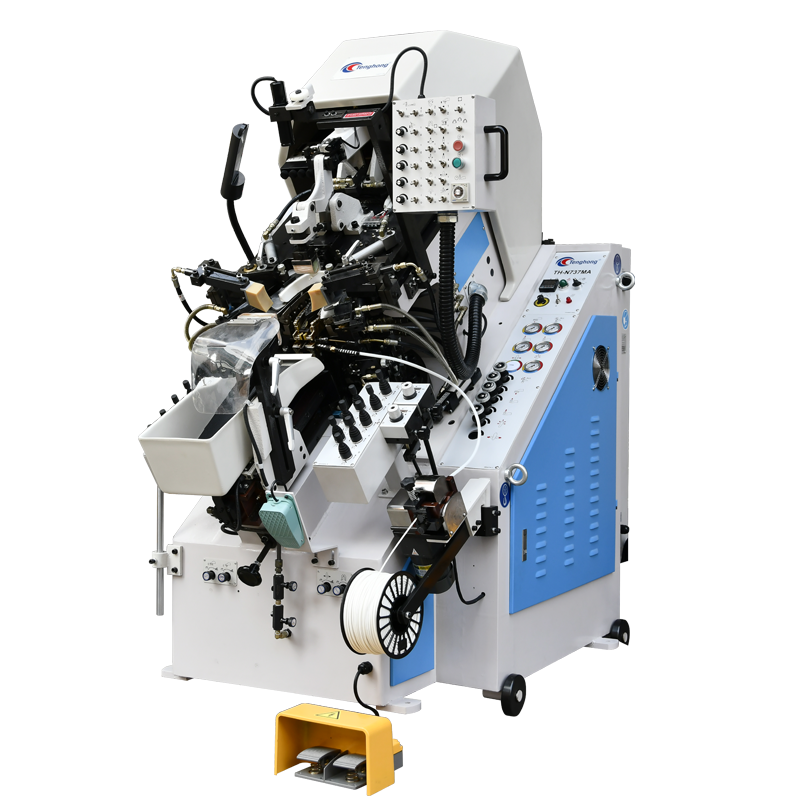

টেংহং অটোমেটেড ভালকানাইজিং প্রেস, চামড়া এবং রাবার প্রক্রিয়াকরণ সরঞ্জাম, স্টিচিং এবং সেলাই মেশিন, সোল গ্রাইন্ডিং এবং পলিশিং ইউনিট এবং কম্বাইন্ড মাল্টি-ফাংশন সিস্টেমসহ পেশাদার পাদুকা মেশিনারির একটি বিস্তৃত পরিসর সরবরাহ করে। প্রতিটি পণ্য বৃহৎ উৎপাদনের জন্য উচ্চ নির্ভুলতা, স্বয়ংক্রিয়তা এবং দক্ষতা প্রদানের জন্য প্রকৌশলীদের দ্বারা তৈরি করা হয়েছে, যাতে বি2বি ক্রেতারা কাজের ধারাবাহিকতা অপ্টিমাইজ করতে এবং নিয়ত উৎপাদনের মান বজায় রাখতে পারেন।

তেংহং সিএনসি মেশিনিং, হাই-স্ট্রেংথ ফ্রেম নির্মাণ, স্বয়ংক্রিয় রোবটিক সংযোজন এবং মাল্টি-অক্ষিস মোশন সিস্টেমসহ অত্যাধুনিক উত্পাদন প্রক্রিয়া ব্যবহার করে। প্রতিটি মেশিন উপাদান যাচাই, চাপ ক্যালিব্রেশন, উত্তাপন সামঞ্জস্যতা পরীক্ষা এবং পারফরম্যান্স সিমুলেশনসহ কঠোর মান পরিদর্শনের মধ্য দিয়ে যায়। শিল্প-গ্রেড ডিজাইন অবিচ্ছিন্ন পরিচালনার অধীনে স্থিতিশীলতা, উচ্চ লোড প্রতিরোধ এবং ন্যূনতম পরিধান নিশ্চিত করে, বি2বি ক্রেতাদের জন্য দীর্ঘস্থায়ী মেশিনারি সরবরাহ করে যা চাহিদা অনুযায়ী উৎপাদন সময়সূচী বজায় রাখতে পারে।