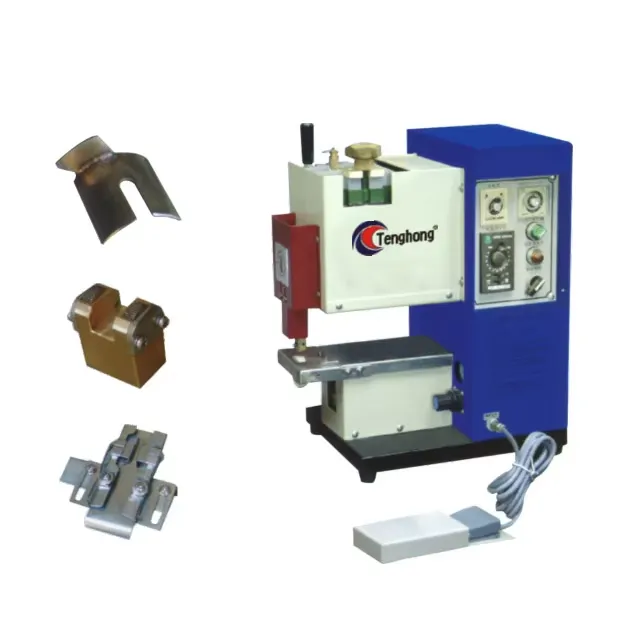

La máquina de adherir suelas por fusión es esencial para fábricas de calzado que buscan mejorar la calidad de unión y la eficiencia en la producción. Guangdong Tenghong Machinery Technology Co., Ltd., con amplia experiencia, presenta el modelo TH-218, con capacidades mejoradas de recubrimiento y un diseño centrado en el usuario.

Esta máquina es adecuada para laminar superficies con un espesor mínimo de 0,5 mm, incluyendo diversos tipos de calzado, productos de cuero, artículos de papelería, cajas de cartón y equipos deportivos. Su sistema ajustable de asiento de ruedas y presión permite una aplicación uniforme del adhesivo en distintos materiales y superficies.

El depósito de adhesivo termofundible está tratado con teflón, lo que facilita el reemplazo del material adhesivo. La temperatura se puede ajustar según las propiedades del adhesivo, evitando eficazmente la carbonización durante la producción. Para mayor seguridad y durabilidad, el motor está equipado con un protector térmico, y la máquina incluye un sistema de extracción para eliminar los olores.

El motor utiliza un control de velocidad por conversión de frecuencia que permite un ajuste de velocidad continuo, adaptándose a diversas necesidades de producción. Un botón de parada de emergencia invierte el funcionamiento del motor para devolver los materiales de manera segura al ser presionado, garantizando la seguridad del operador.