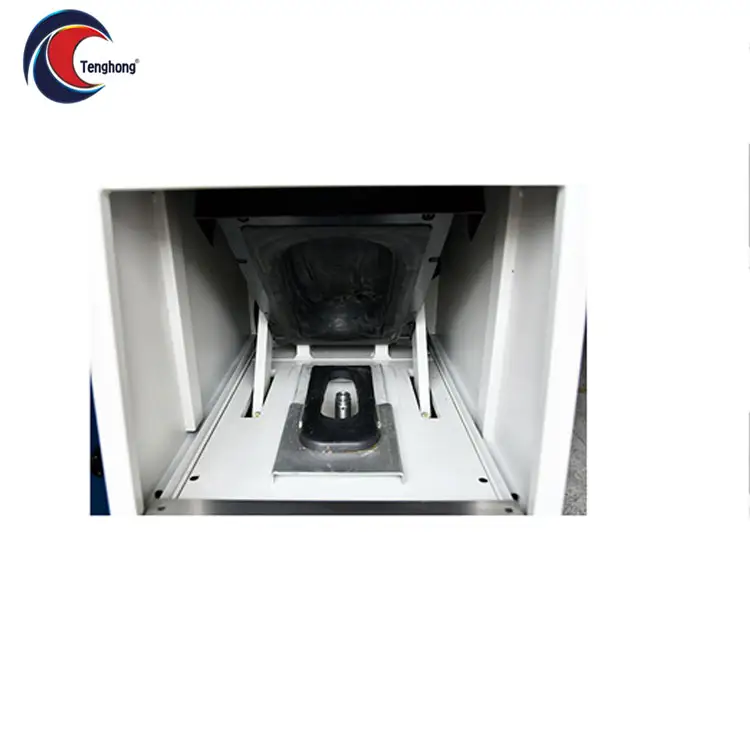

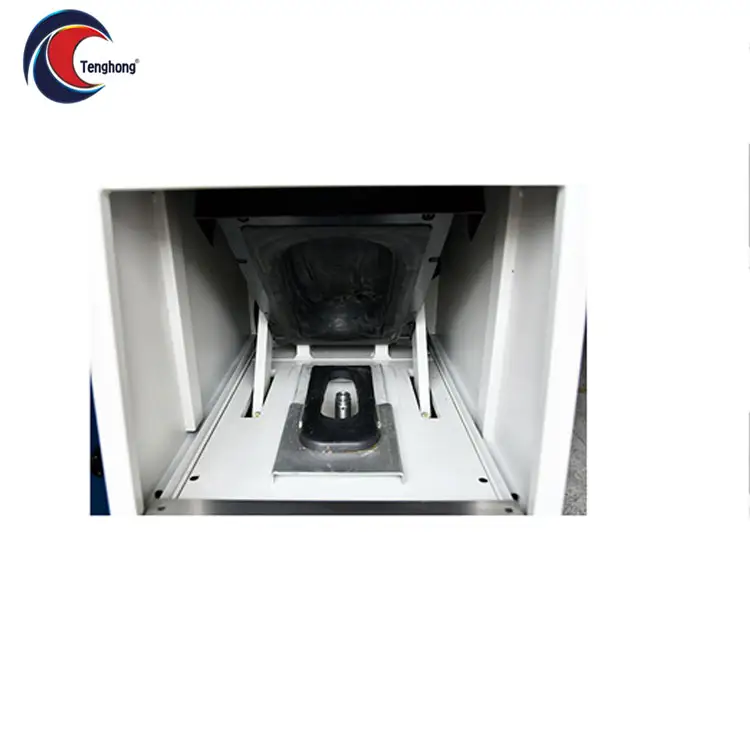

Guangdong Tenghong Machinery Technology Co., Ltd. adalah produsen dan pemasok terkemuka mesin sepatu di Tiongkok. Mesin pengaplikasi sol pneumatik unggulan mereka, TH586A, dilengkapi teknologi pneumatik canggih yang dikombinasikan dengan desain keselamatan pintar, menawarkan mode operasi otomatis dan manual untuk memenuhi kebutuhan perekatan sol sepatu.

Dirancang dengan suplai listrik standar 220V 50Hz, waktu kompresi yang dapat diatur antara 0 hingga 99 detik, serta konsumsi daya rendah sebesar 0,2KW, mesin ini memanfaatkan udara terkompresi pada tekanan 0,6MPa secara efisien. Dengan berat 275kg dan dimensi yang dioptimalkan untuk integrasi lancar ke dalam lini produksi yang sudah ada, mesin ini mendukung manufaktur sepatu yang efisien dan fleksibel.

Sebagai merek terkemuka di industri peralatan sepatu Tiongkok, Tenghong Machinery menyediakan solusi profesional dan layanan purna jual yang komprehensif, membantu para produsen meningkatkan kualitas produk dan kinerja operasional sekaligus memajukan otomatisasi.