Guangdong Tenghong Machinery Technology Co., Ltd. is a solutions-driven manufacturer specializing in advanced equipment for shoe and bag production since 2000. Headquartered in Houjie, Dongguan, the company focuses on turning engineering rigor into predictable outcomes for global factories. For buyers comparing footwear making machine price proposals, Tenghong emphasizes measurable lifecycle value: durable frames, energy-saving drives, and PLC architectures that are simple to operate yet robust for three-shift duty. Over 150 engineers and technicians power an integrated R&D and production workflow, aligning mechanical design, electronics, and software so customers receive consistent performance from FAT to mass production.

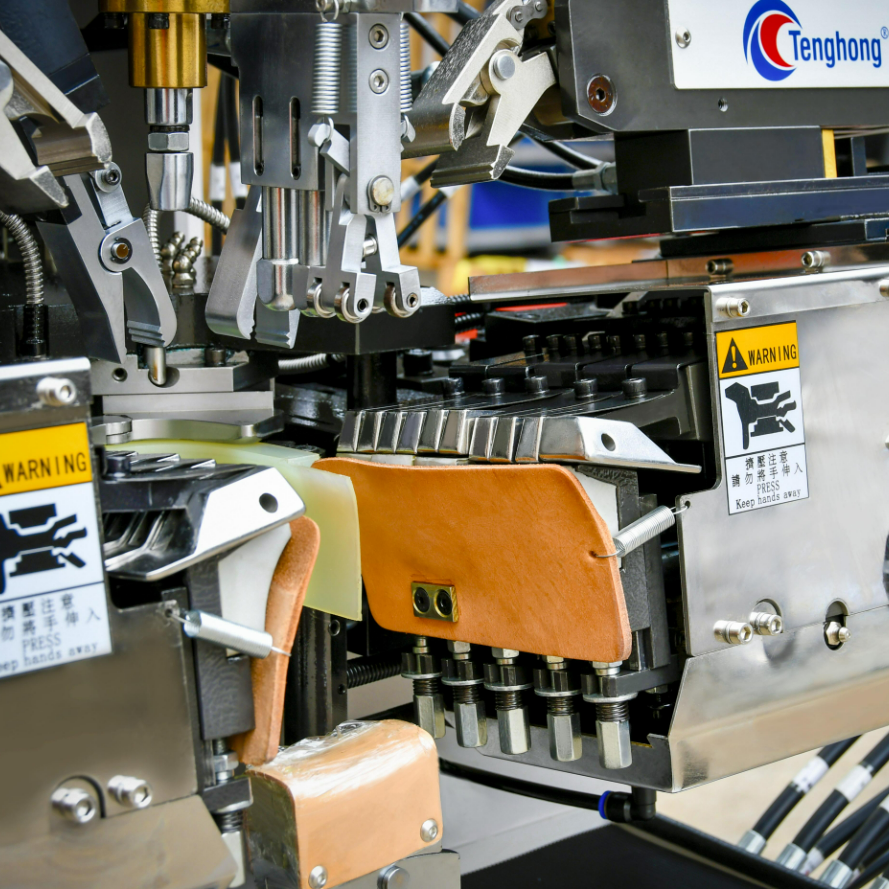

Tenghong’s portfolio spans cutting, stitching, molding, vulcanizing, roughing, finishing, and automated handling. Each platform is built around maintainability—clear cable routing, modular boards, standardized actuators, and accessible wear parts. When customers scrutinize total ownership beyond a quoted footwear making machine price, they find tangible safeguards: CE/ISO certifications, ISO9001-based quality systems, and traceable components from vetted suppliers. This discipline reduces variability in high-mix environments where leather, fabric, and synthetic materials demand different thermal and pressure profiles.

Service is structured to de-risk commissioning. Pre-sale consulting translates target takt time and yield into machine configurations and line balancing. During installation and debugging, field teams calibrate temperature, pressure, and alignment windows to local materials and adhesives. Post-sale, remote diagnostics, firmware updates, and spare-part SLAs maintain uptime. By bundling training and maintenance planning, Tenghong helps customers convert a quoted footwear making machine price into a predictable payback schedule anchored by OEE improvements and scrap reduction.

The company’s culture blends practical engineering with continuous improvement. Lessons from global deployments—Southeast Asia, Europe, and other regions—feed back into enclosure design, HMI usability, and energy management. Whether a plant needs a compact cell for new SKUs or a multi-station line upgrade, Tenghong scales solutions without forcing a full retrain. Financing support and structured upgrade paths further stabilize budgets, letting manufacturers phase in robotics, IIoT dashboards, or extra tooling under a controlled footwear making machine price framework. The result is a long-term partner who aligns machine capability, service discipline, and total cost with the realities of industrial footwear production.