Founded in 2000 and headquartered in Dongguan, China, Guangdong Tenghong Machinery Technology Co., Ltd. is a pioneering manufacturer focused on the design, development, and production of high-tech shoe manufacturing equipment. With a multidisciplinary team of over 150 professionals, including engineers and service experts, Tenghong has developed a reputation for delivering robust, intelligent, and efficient machinery solutions to the global footwear industry.

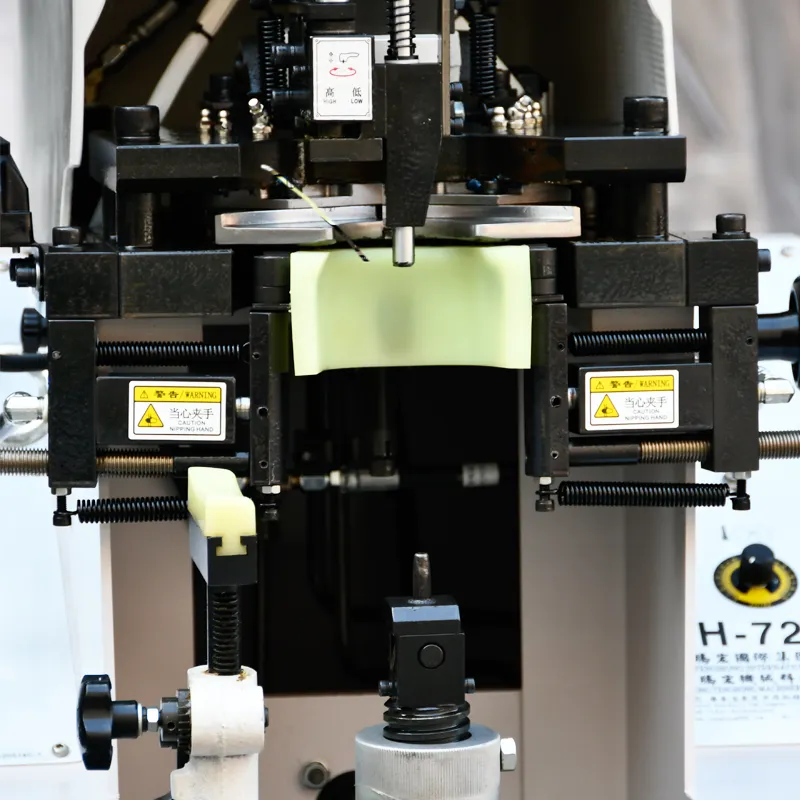

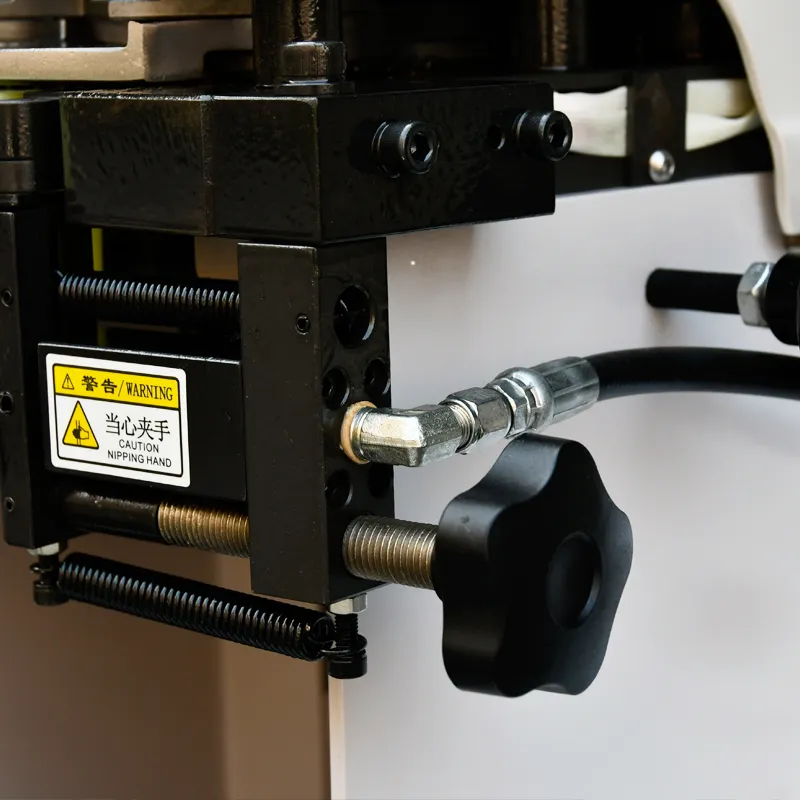

The company offers a comprehensive product portfolio including toe lasting machines, heavy-duty sole attaching machines, hydraulic heel seat lasting machines like the TH-727A, and automatic toe lasting machines featuring advanced servo and visual trajectory controls. Committed to ISO9001 quality management systems, Tenghong continually integrates international technology standards and innovative design concepts, ensuring its products maintain competitive advantages in performance and cost-effectiveness. Their dedication to customer service covers the complete life cycle of machinery, from pre-sales consulting and plant design to sales, installation, debugging, and after-sales maintenance. This holistic approach allows Tenghong to meet diverse client needs and support the transformation towards intelligent, automated footwear production.