Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 in Dongguan, China, specializes in designing and manufacturing high-quality footwear machinery, including shoes upper making machines. With over 20 years of experience, Tenghong has become a leading supplier of innovative, reliable solutions for both small workshops and industrial-scale factories.

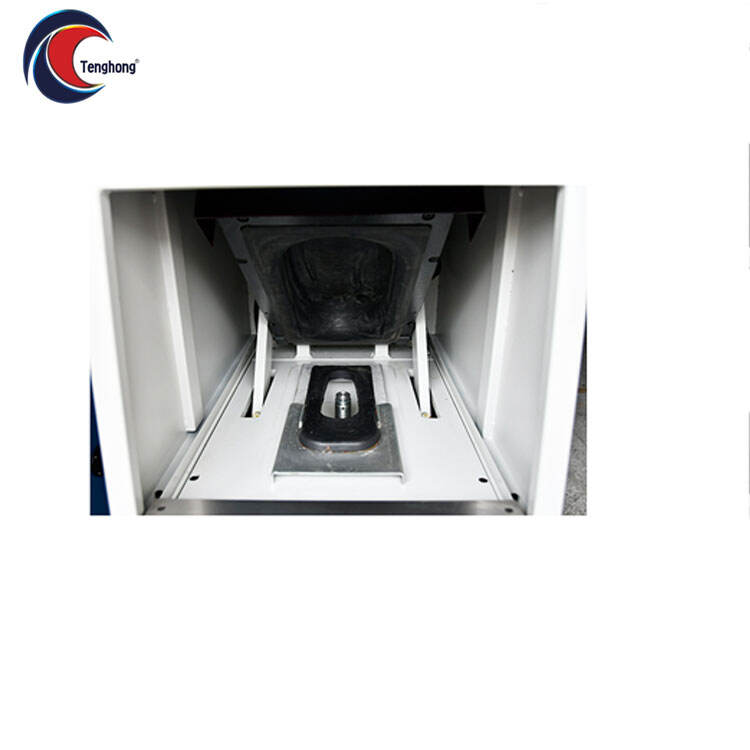

The shoes upper making machine demonstrates Tenghong’s commitment to precision, efficiency, and safety. It integrates cutting, stitching, shaping, and finishing into one automated system. The machine accommodates leather, fabric, and synthetic materials, ensuring consistent upper quality across multiple shoe designs. Adjustable pressure, PLC control, and automated feeding enhance flexibility, enabling manufacturers to switch between models without equipment replacement.

Tenghong strictly adheres to ISO9001 standards, and all machines are CE-certified for international compliance. Each shoes upper making machine undergoes extensive testing, including accuracy checks, durability assessments, and production simulations, ensuring reliable operation under continuous, high-volume production.

The company provides comprehensive support services: pre-sale consultation, installation, operator training, and after-sales maintenance. IoT monitoring, remote diagnostics, and software upgrades further improve long-term performance.

With a dedicated R&D team of over 150 engineers and technicians, Tenghong continues to innovate in footwear machinery. Its global presence spans Southeast Asia, Europe, and Latin America, providing factories worldwide with high-efficiency shoes upper making machines. Guided by the philosophy “mutual benefit and ideal achievements,” Tenghong ensures every machine delivers precision, consistency, and long-term value, helping manufacturers scale production efficiently while maintaining high-quality standards.