Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 in Houjie, Dongguan, is a leading manufacturer of high-tech footwear machinery, specializing in B2B solutions for export-oriented factories. Tenghong develops, produces, and sells a wide range of shoe-making equipment, including shoe maker machines for sale, cutting machines, punching machines, stitching machines, sole pasting systems, and multi-function combination units.

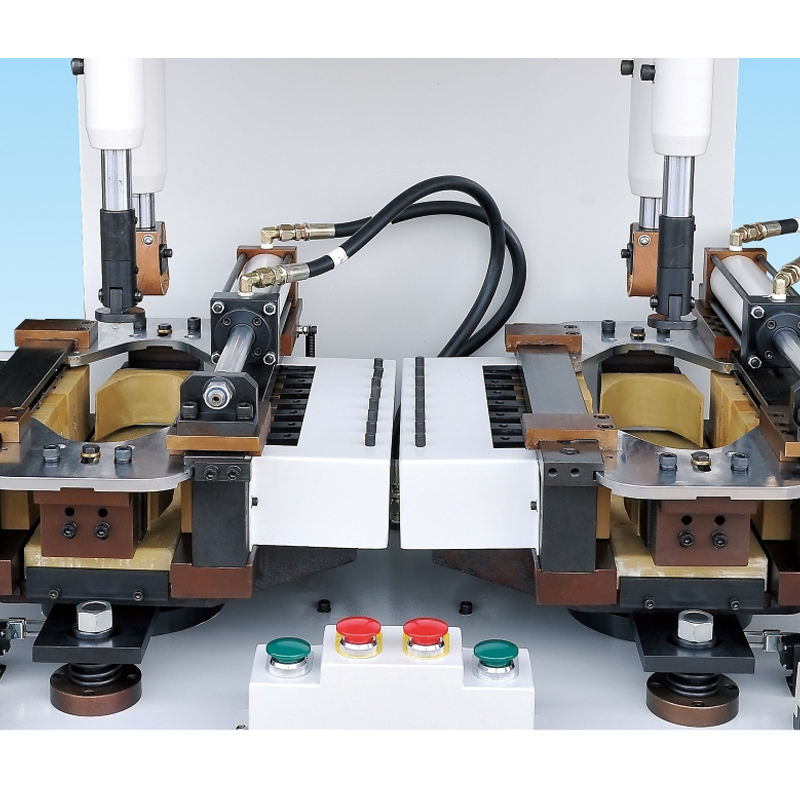

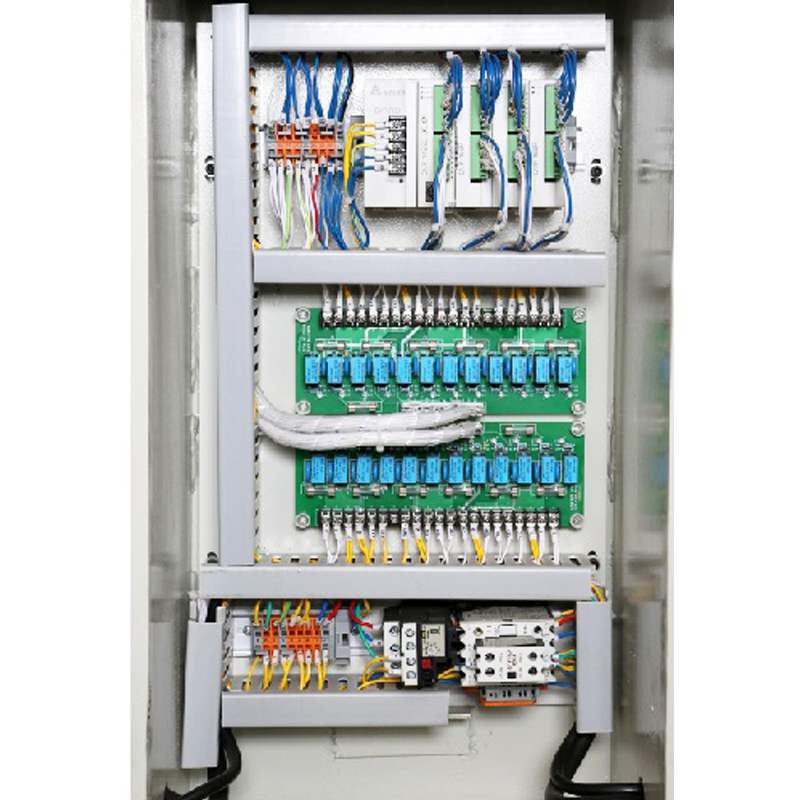

Tenghong serves small workshops, medium-sized factories, and large-scale B2B export factories, providing machinery designed for precision, automation, and durability. Shoe maker machines for sale are engineered to handle leather, synthetic, and fabric shoes, delivering consistent cutting, stitching, and sole pasting with minimal material waste. Modular tooling enables quick adaptation to various shoe designs and sizes. PLC-controlled operations, automated feeding, and intelligent pressure and temperature management reduce labor dependency and maintain consistent quality.

With a team of over 150 engineers and technical staff, Tenghong provides comprehensive pre-sale consultation, installation, operator training, commissioning, and after-sales maintenance services. All machinery meets ISO9001:2008 and CE standards, ensuring compliance with international quality, safety, and environmental requirements. IoT connectivity allows real-time monitoring, predictive maintenance, and workflow optimization, enhancing efficiency and reliability. Tenghong emphasizes innovation, teamwork, and customer satisfaction. Advanced R&D, combined with stringent quality control, ensures high-performance machinery for B2B export footwear production. Long-term partnerships across Southeast Asia, Europe, and the Middle East demonstrate Tenghong’s commitment to delivering reliable, efficient, and high-quality shoe-making equipment for global manufacturers.