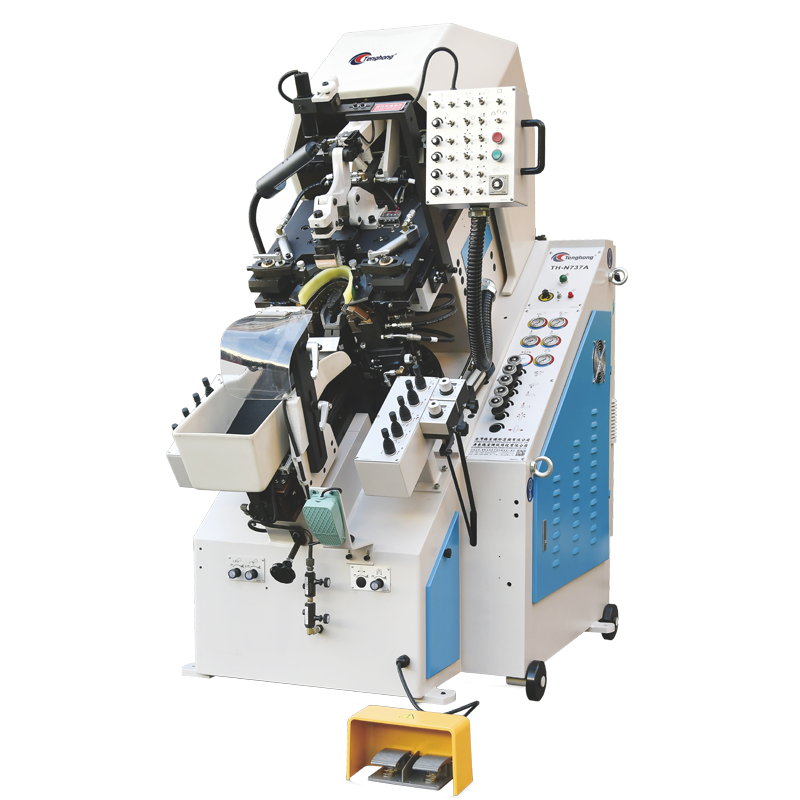

Guangdong Tenghong Machinery Technology Co., Ltd., established in 2000 in Houjie, Dongguan, has grown into a global leader in shoemaking and leather machinery manufacturing. Specializing in advanced B2B equipment solutions, the company provides shoemaking production lines, sole attaching machines, eyeleting machines, dyeing machines, and more, serving footwear and leather goods manufacturers worldwide.

Tenghong has built a reputation on innovation, precision, and service. With over 150 highly skilled engineers, technicians, and R&D experts, the company has developed an extensive product portfolio that covers every stage of shoemaking. All machines are designed with industrial-grade durability, modular structures, and automation features that reduce manual labor while ensuring consistent product quality. Tenghong’s shoemaking production line purchase options allow global factories to upgrade to Industry 4.0 standards, including IoT-enabled monitoring, MES/ERP integration, and predictive maintenance.

Quality assurance is at the heart of Tenghong’s philosophy. Each piece of equipment is built under strict ISO9001 management and certified with CE compliance, ensuring international safety and performance standards. Products undergo rigorous stress testing, long-cycle operation trials, and precision calibration to guarantee long-term reliability. This dedication to durability makes Tenghong machinery a long-term investment for B2B buyers seeking sustainable growth.

Beyond manufacturing, Tenghong offers a complete service system: pre-sales planning, personalized consultation, installation, debugging, operator training, and after-sales maintenance. With a global spare parts supply chain and remote support capabilities, clients are assured of uninterrupted operations.

Tenghong’s culture emphasizes teamwork, innovation, and customer satisfaction. Their mission—“mutual benefit and ideal achievement”—drives continuous improvement and product innovation. By combining advanced foreign technology with in-house expertise, Tenghong delivers practical and cost-effective solutions tailored to the diverse needs of international footwear factories.

With over two decades of expertise and a growing global presence in Southeast Asia, Europe, and beyond, Tenghong is not just a machinery supplier but a strategic partner for B2B clients pursuing efficiency, scalability, and sustainable success in shoemaking.