Optimizing Shoe Manufacturing Processes with Advanced Machinery

Automation in Shoe Sewing & Stitching Operations

The footwear industry has changed a lot since automation came into play for shoe sewing and stitching work. Robotic systems now do most of what used to take hours of manual labor. Companies save money on wages while getting better control over product quality. Take those fancy shoe sewing machines with built-in robotics they've been installing lately. These machines handle tricky stitching jobs much more accurately than humans ever could, which means fewer mistakes and shoes that look consistent across the board. Some factories report error rates dropping by half after switching to automated systems.

Big names across manufacturing are turning to robots to crank up production speeds. Shoe factories specifically have seen dramatic changes after installing automated stitching systems. Lead times dropped significantly while output shot through the roof. A study from the Footwear Distributors and Retailers of America points out that labor costs fell around 30% thanks to these machines working around the clock. For many businesses, getting this tech onboard isn't just nice to have anymore it's practically necessary if they want to keep prices competitive and satisfy customers who always seem to want more shoes faster than ever before.

Precision Engineering with Shoe Production Machines

Precision engineering technologies have significantly improved the accuracy and quality of shoe production. These advanced systems enable manufacturers to create intricate designs and handle repetitive processes with exceptional precision. CNC machines, for example, are indispensable in crafting detailed patterns and consistent components essential for high-quality footwear.

Shoe manufacturing machines designed for particular footwear types offer customized options for different market niches. For instance, there are machines specifically built for sneaker production versus those used for boots or dress shoes. These specialized tools help maintain quality control when companies produce thousands of pairs at once. Industry professionals stress how precise measurements matter a lot for keeping product quality uniform while also making sure shoes last longer after purchase. Many modern shoe factories now invest in advanced machinery equipped with computer guided systems. This tech helps cut down on material waste during production, which is good news for manufacturers trying to adopt greener practices without sacrificing output efficiency.

Advanced Adhesive Application Machinery for Optimal Efficiency

Hot Melt Adhesive Edge Coating Machine: Eco-Friendly Bonding Solutions

The hot melt adhesive tech is changing how shoes get made thanks to better sticking power and being kinder to the environment. Traditional ways needed lots of release paper, but these new adhesives stick just fine without them, even on all those weird shaped parts that come together in shoe construction. The environmental angle is pretty big too since there's way less waste generated during production and factories stay cleaner overall. Shoe companies adopting this stuff actually help their sustainability goals quite a bit. Many brands have already switched over and noticed real improvements in product longevity plus significantly less material going into landfills. Some studies back this up showing products last longer when using hot melt adhesives compared to older methods, which means fewer replacements down the line for consumers as well.

Dispensing Machine: Versatile Glue Application for Complex Designs

In shoe manufacturing, dispensing machines have become essential tools for applying glue in ways that work well for complicated designs. These machines handle the glue application automatically with pretty good precision, which means manufacturers get just the right amount of adhesive without wasting too much material. What makes them really valuable is their ability to be customized according to different production needs. For instance, companies can tweak settings to match specific patterns or materials they're working with. Looking at real world applications, factories report that when they upgrade to better dispensing tech, they see noticeable improvements in both productivity and reduced waste. That's why many footwear producers now consider these machines fundamental parts of their operations rather than optional extras.

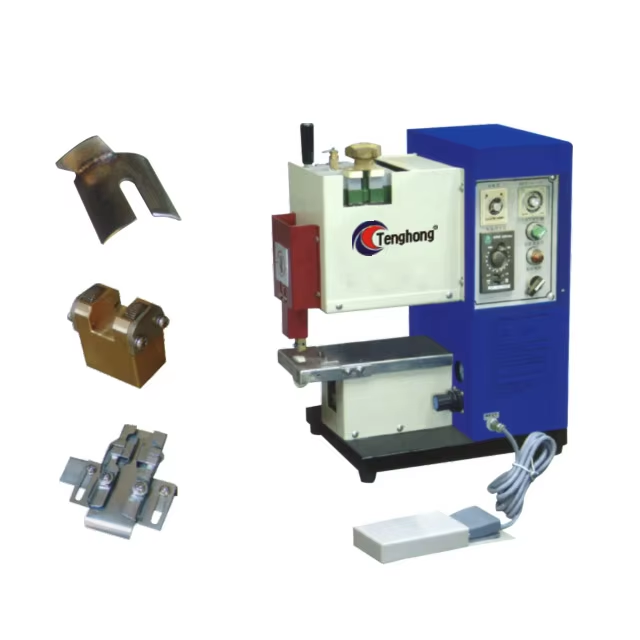

Sealed Type Adhesive Machine: Maintenance-Free Operation

Adhesive machines with sealed designs bring real benefits to operations, mainly because they don't require much maintenance at all. Traditional gluing systems tend to lose effectiveness over time as the adhesive evaporates or hardens inside the machine. But with sealed units, everything stays contained so the glue remains workable for longer periods between cleanings. For factory owners, this means fewer production stoppages and better output rates across the board. The money saved on repairs and wasted materials adds up significantly after several months of operation. Many plant managers we've spoken to report that these sealed machines just keep going day after day without issues, which makes them stand out in today's tough manufacturing landscape where every minute counts.

Overcoming Production Challenges Through Automation

Reducing Labor Dependency in Shoe Making Processes

Shoe manufacturers are turning to automation because they need alternatives to their growing reliance on human labor. Labor markets just aren't what they used to be these days. Costs keep climbing and finding good workers who know how to do the job right? That's becoming harder every year. Machines have stepped into this gap, handling those boring, physically demanding jobs that nobody wants to do anymore. Think about it: cutting fabric pieces, sewing them together, putting shoes together piece by piece – all these things machines can now handle better than people ever could. And when factories automate these processes, they don't just save money on wages. The end result tends to be consistently better quality products too since robots don't get tired or distracted like humans sometimes do.

Industry reports are showing something pretty interesting happening with workforce needs because of all this automation stuff going on. Take for example one recent research paper that pointed out how automated systems can cut down on labor expenses by roughly thirty percent during certain parts of making shoes. And it looks like this isn't just a passing thing either. Many people who know what they're talking about believe we'll see even more machines taking over tasks in coming years. What does this mean for workers? Well, instead of doing repetitive physical work all day long, employees might find themselves monitoring equipment and checking product quality more often. Some factories already have workers whose main job is just watching over robotic arms and stepping in when something goes wrong.

Minimizing Material Waste with Precision Systems

Shoe factories are seeing major changes thanks to precision systems that cut down on wasted materials. The new tech helps manufacturers track exactly how much fabric or leather they need for each pair, so there's less leftover scraps piling up at the end of production runs. With automated cutting machines and software that calculates material needs down to the last centimeter, companies can make better use of their supplies. Some factories report saving thousands of dollars monthly just from smarter material handling. What was once considered normal waste in shoemaking is now being turned into something valuable through these advanced manufacturing approaches.

Companies that install precision systems typically save a lot on costs. Some research indicates factories might cut their material expenses by around 20 percent after switching to these kinds of systems. Environmental experts keep pointing out how cutting down on waste matters a lot for making manufacturing greener. When factories produce less waste, they're actually doing something good for the planet while still running efficiently. This makes sense given all the pressure nowadays to make production processes more environmentally friendly across different industries worldwide.

Sustainable Innovations in Shoe Manufacturing Machinery

Energy-Efficient Operation Modes

The shoe manufacturing business is seeing major changes thanks to energy efficient machinery that cuts down on carbon emissions during production. Newer equipment manages power usage better without sacrificing how well things run on the factory floor. Companies have started implementing tech like variable frequency drives or VFDs along with energy recovery systems across their operations. Take stitching machines for instance these days they come equipped with VFD technology which lets them adjust motor speeds based on what's actually needed at any given moment. This means less wasted electricity when machines aren't working flat out all day long.

Many footwear companies across Asia have started implementing energy saving measures and seen real results from these changes. Take for example the factory owners in Vietnam who replaced their old machinery with newer models designed to consume less power. These upgrades cut down on monthly electricity costs while simultaneously reducing carbon footprints. According to research published by IEA last year, businesses embracing such efficiency improvements typically see around 18-20% drops in overall energy usage along with significant emission reductions. What makes all this worthwhile is that going green isn't just good for the planet anymore it actually saves money too, which explains why more manufacturers keep looking into these options despite initial investment costs.

Recycling Capabilities in Adhesive Systems

The reuse of adhesive materials during shoe production presents some pretty good chances for being greener. Back in the day, most glues used to stick shoes together couldn't actually be recycled at all, which created major problems for the environment. Things are changing though. New technology has made it possible to recycle certain kinds of adhesives now, which is helping make shoe manufacturing much more sustainable overall. Water based glues and those polyurethane ones seem to work best for recycling efforts. This means factories can throw away less stuff and cut down on how bad they affect nature. Some companies are already seeing real benefits from switching to these recyclable options.

New adhesive formulas are starting to include recycled content, helping push forward those closed loop systems we all hear so much about. Take some recent developments where manufacturers create adhesives that actually break down completely at end of life, letting components get reused again and again. This fits right into that circular economy thing that's gaining traction across industries. Major players like Henkel and 3M have already rolled out their own recycling programs for old adhesives, showing real world results from going green. Research indicates that when companies recycle their adhesive waste instead of sending it to landfills, they cut down on carbon emissions by around 15%. That kind of number makes a strong case for why recycling should be part of any serious sustainability strategy in manufacturing today.