The hydraulic sole press machine represents a significant advancement in footwear manufacturing technology, offering unparalleled precision and efficiency in sole attachment processes. Guangdong Tenghong Machinery Technology Co., Ltd., established in 2000 in Dongguan, China, has been at the forefront of developing such innovative machinery. With over two decades of industry experience and a team of more than 150 skilled professionals, the company has built a reputation for delivering high-quality, reliable equipment that meets the evolving needs of global footwear manufacturers.

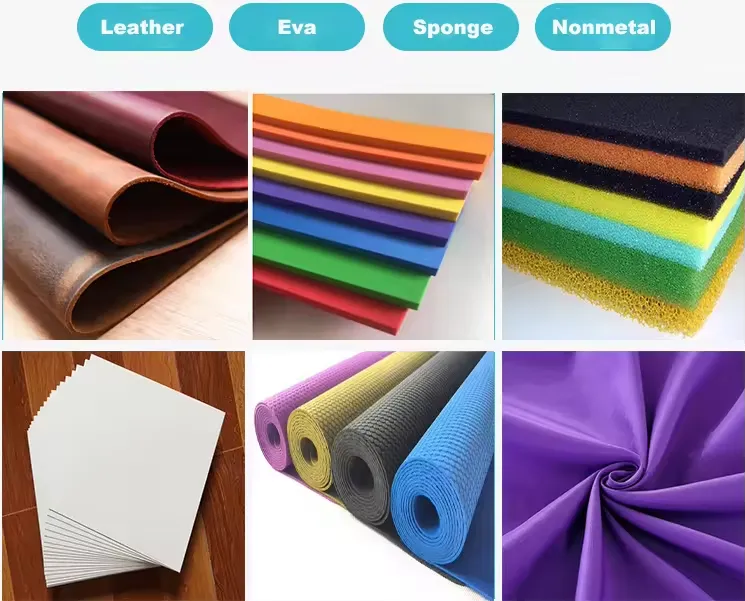

The application scenarios for our hydraulic sole press machine are diverse and comprehensive. It is extensively used in the production of athletic footwear, where precise sole bonding is crucial for performance and durability. The machine equally serves safety boot manufacturers who require robust and reliable sole attachment to meet industry standards. Fashion footwear producers benefit from its ability to handle delicate materials and intricate designs without compromising quality. The hydraulic system ensures consistent pressure application across various sole types, including rubber, PVC, TPU, and EVA materials, making it suitable for virtually any footwear production requirement.

One of the machine's standout features is its ability to maintain consistent pressure throughout the bonding process, ensuring uniform adhesion across the entire sole surface. This is particularly important for footwear that undergoes strenuous use, as it prevents sole separation and extends product lifespan. The adjustable pressure settings allow manufacturers to customize the bonding process for different materials and designs, while the automated operation reduces labor costs and minimizes human error.

Guangdong Tenghong Machinery leverages its ISO9001:2008 certification and extensive industry expertise to deliver products that exceed quality expectations. The company provides comprehensive support services, including pre-sale consultations to determine the most suitable machine configuration, professional installation, thorough operator training, and reliable after-sales maintenance. This holistic approach ensures that clients receive not just equipment, but complete solutions tailored to their specific production requirements.

The hydraulic sole press machine's efficiency is further enhanced by its energy-saving features and low maintenance requirements. The hydraulic system operates with optimal energy efficiency, reducing power consumption compared to traditional mechanical systems. Additionally, the machine's durable construction and high-quality components minimize downtime and repair costs, ensuring continuous production and maximum return on investment.

In today's competitive footwear market, quality and efficiency are paramount. Our hydraulic sole press machine addresses both these aspects by delivering consistent, high-quality results while optimizing production processes. Whether for established manufacturers looking to upgrade their equipment or new facilities setting up production lines, this machine offers the reliability and performance needed to succeed in the global footwear industry.