Guangdong Tenghong Machinery Technology Co., Ltd. is a trusted leader in the field of high-tech shoe machinery manufacturing. Founded in 2000 in Houjie, Dongguan, the company has more than two decades of expertise in producing and exporting advanced equipment for the global footwear industry.

Our company focuses on providing innovative, reliable, and cost-effective solutions that meet the growing demands of professional footwear manufacturers. With CE-certified and ISO9001-compliant products, Tenghong ensures that every piece of machinery adheres to international standards of quality and safety. Today, our machines are widely used across Asia, Europe, and other global markets, supporting the production of both fashion and functional footwear, including medical, orthopedic, and work shoes.

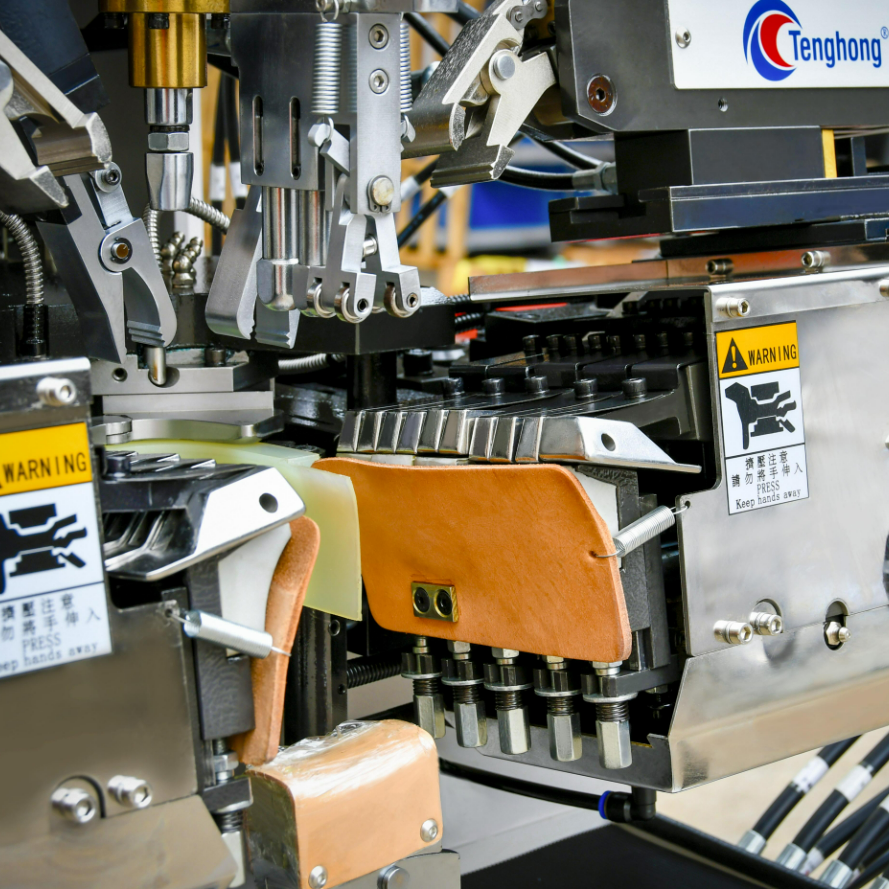

We have built a strong R&D capability with over 150 highly skilled engineers and technicians. This elite team is dedicated to developing and refining shoe production machinery that integrates cutting-edge technologies such as CNC precision systems, industrial IoT, multi-axis robotics, and machine vision. The result is equipment that achieves superior efficiency, precision, and long-term stability.

Our service model covers the entire lifecycle of customer engagement: pre-sale consultation and planning, in-sale installation and commissioning, and post-sale training and maintenance. Customers benefit from our global support network, rapid spare parts supply, and continuous software updates, ensuring maximum uptime and production efficiency.

The company culture is deeply rooted in the principles of innovation, teamwork, and customer satisfaction. Tenghong believes in creating mutual benefits with clients and fostering long-term partnerships. By consistently improving our machinery and processes, we help footwear manufacturers worldwide achieve their production goals while reducing costs and maintaining quality.

With our advanced production facilities, experienced workforce, and customer-centric approach, Tenghong has become a leading supplier of shoe machinery solutions. Whether for medical shoe equipment, work shoe production machines, or automated assembly systems, we are committed to delivering technology that empowers our customers to stay competitive in the global footwear market.