As footwear manufacturing advances, integrating intelligent automation becomes essential. The automatic toe lasting machine significantly enhances production consistency and reduces setup times. Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000, comprises a team of over 150 professionals specialized in developing advanced shoe machinery. Their product range includes hydraulic and pneumatic machines, including automatic toe and heel lasting units, serving various production needs.

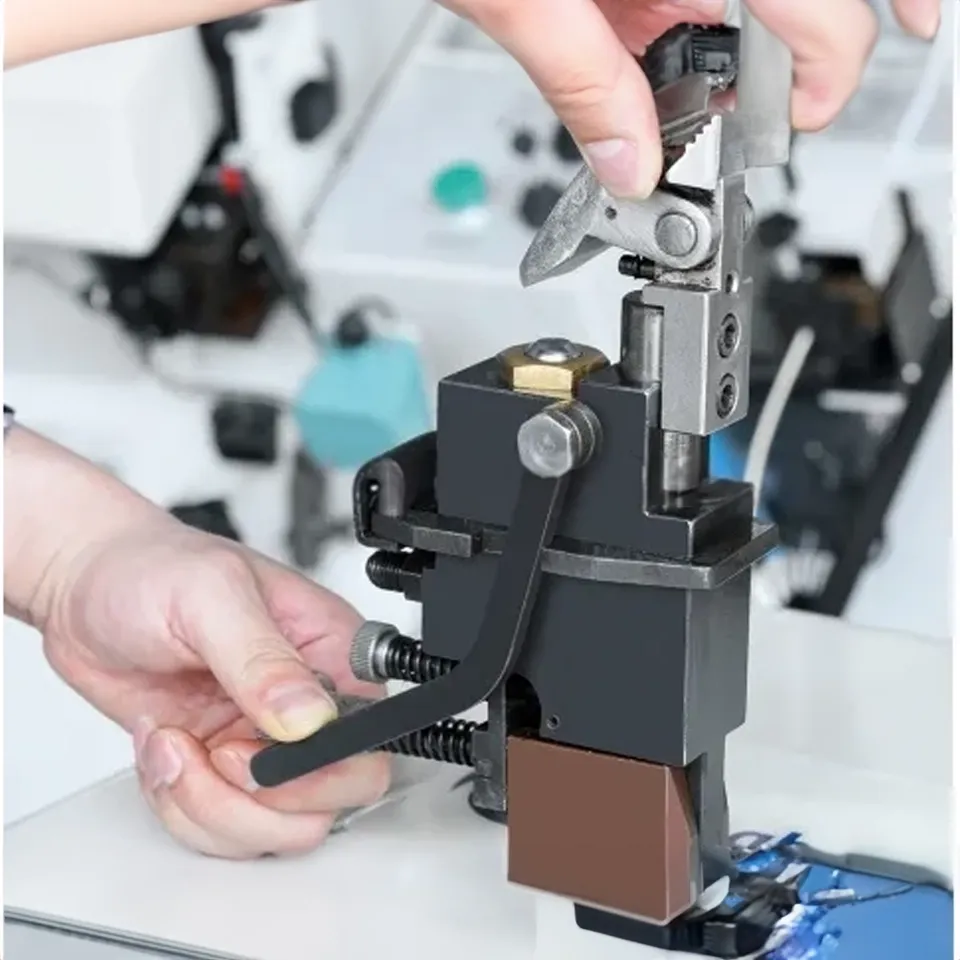

The TH-739B model utilizes digitized position indicators to achieve repeatability up to 0.1mm during lasting. An integrated encoder replaces manual adjustments, enabling faster setup and smoother operation. The dual-speed settings protect sensitive uppers from damage by adapting the lift rate. Seven pincers allow versatile adaptation to different shoe lasts.

Auxiliary wipers and automatic cementing units can be optionally added to optimize workflow and improve outcome consistency. Tenghong offers comprehensive support from pre-sale planning to installation, training, and maintenance, ensuring reliable operation. This combination of innovative technology and customer-focused solutions positions Tenghong as a trusted partner worldwide.