2000 সালে প্রতিষ্ঠিত, গুয়াংডং টেংহং মেশিনারি টেকনোলজি কোং লিমিটেড ইন্টিগ্রেটেড জুতা উত্পাদন সিস্টেমে বিশেষজ্ঞ। নবায়ন এবং নির্ভরযোগ্যতার জন্য পরিচিত, টেংহং বৈশ্বিক জুতা বাজারের জন্য উন্নত মেশিনারি সমাধান প্রদান করে। কোম্পানির স্বয়ংক্রিয় উত্পাদন সিস্টেমগুলি প্রক্রিয়াগুলি স্ট্রিমলাইন করতে এবং স্কেলযোগ্য দক্ষতা নিশ্চিত করতে রোবোটিক্স, সিএনসি নির্ভুলতা এবং আইআইওটি প্রযুক্তি একত্রিত করে। সিই এবং আইএসও দ্বারা প্রত্যয়িত, টেংহংয়ের সরঞ্জাম এশিয়া, ইউরোপ এবং তার বাইরে বিশ্বস্ত। শক্তিশালী প্রায়োগিক দল এবং ব্যাপক গ্রাহক সমর্থন সহ, কোম্পানিটি গুণগত মান এবং নবায়নের ভিত্তিতে দীর্ঘমেয়াদী অংশীদারিত্ব গঠনে নিবদ্ধ।

টেংহং প্রিল-সেল পরামর্শ, সাইট মূল্যায়ন, উৎপাদন পরিকল্পনা, ইনস্টলেশন, অপারেটর প্রশিক্ষণ, কমিশনিং এবং পরবর্তী বিক্রয় রক্ষণাবেক্ষণসহ প্রান্ত থেকে প্রান্ত পর্যন্ত সমর্থন প্রদান করে। বহুভাষিক প্রায়োগিক সমর্থন এবং দূরবর্তী সমস্যা সমাধানের মাধ্যমে নিশ্চিত করা হয় যে আন্তর্জাতিক ক্রেতারা যাতে যন্ত্রপাতি কার্যকরভাবে পরিচালনা করতে পারেন এবং সর্বনিম্ন ব্যতিক্রমে চলমান উৎপাদন বজায় রাখতে পারেন।

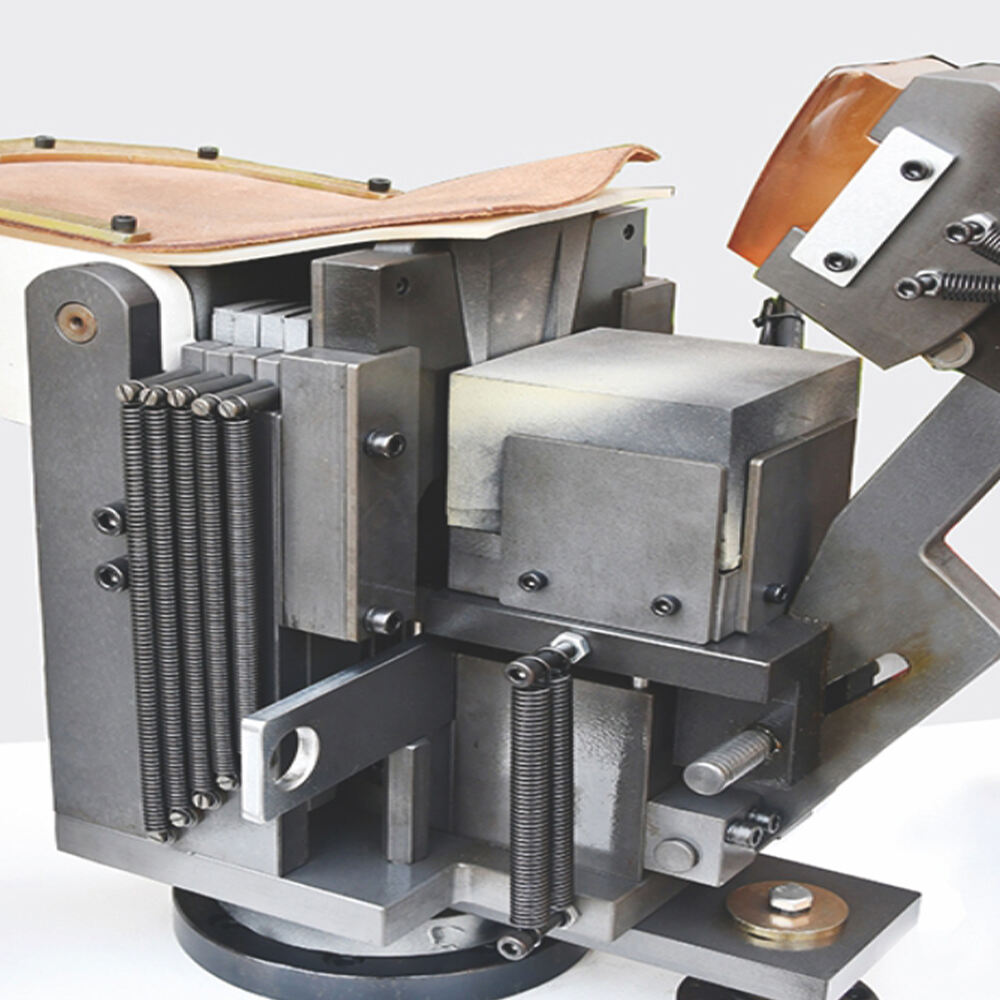

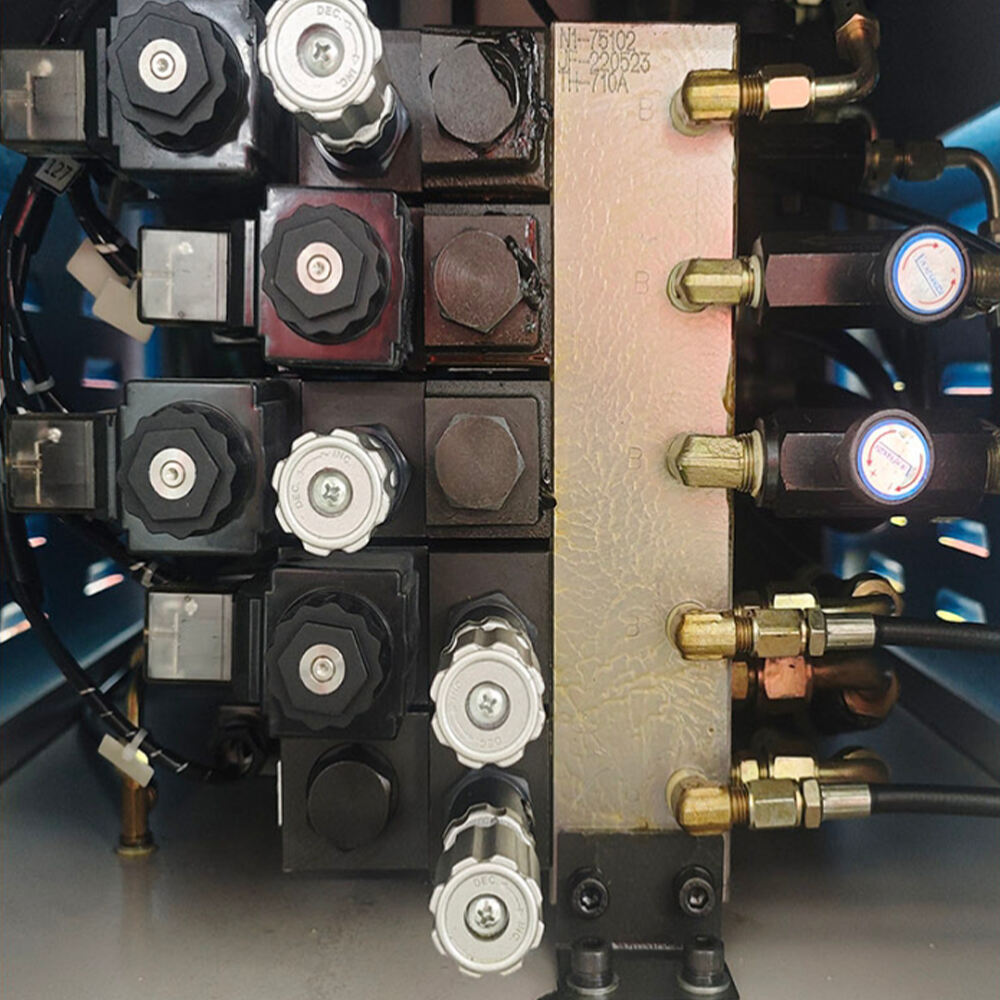

টেংহং যন্ত্রপাতির মধ্যে বিনিয়োগ করে বি2বি ক্রেতাদের কাছে টেকসই, উচ্চ-দক্ষতাসম্পন্ন সরঞ্জাম যোগান দেওয়া হয় যা দীর্ঘমেয়াদি নির্ভরযোগ্যতা এবং পরিচালনার স্কেলযোগ্যতা প্রদান করে। শিল্পমানের উপাদান, স্বয়ংক্রিয়তা এবং বুদ্ধিমান নিয়ন্ত্রণ ব্যবস্থা মাধ্যমে নিশ্চিত করা হয় যে উৎপাদনের মান স্থিতিশীল থাকে, রক্ষণাবেক্ষণ সর্বনিম্ন হয় এবং বিনিয়োগের প্রত্যাবর্তন হয় সর্বোচ্চ, এবং এর মাধ্যমে টেংহং যন্ত্রপাতি পেশাদার জুতা প্রস্তুতকারকদের জন্য একটি কৌশলগত সম্পদে পরিণত হয়।