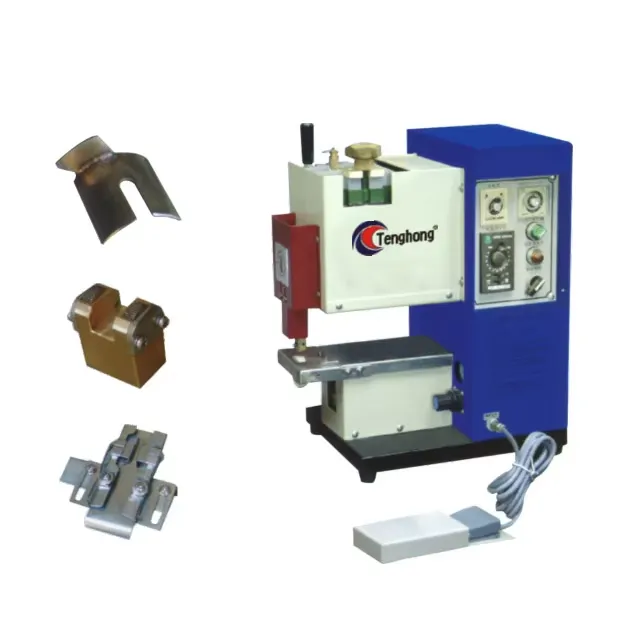

হট মেল্ট সোল আটাচিং মেশিনটি ফুটওয়্যার কারখানাগুলির জন্য অপরিহার্য যারা বন্ডিং গুণমান এবং উৎপাদন দক্ষতা উন্নত করতে চায়। গুয়াংডং টেংহং মেশিনারি টেকনোলজি কোং লিমিটেড, যার ব্যাপক দক্ষতা রয়েছে, TH-218 মডেলটি প্রদর্শন করছে, যাতে উন্নত কোটিং ক্ষমতা এবং ব্যবহারকারী-কেন্দ্রিক ডিজাইন রয়েছে।

এই মেশিনটি 0.5 মিমি ন্যূনতম পুরুত্ব সহ বিভিন্ন পৃষ্ঠের ল্যামিনেটিংয়ের জন্য উপযুক্ত, বিভিন্ন জুতা, চামড়ার পণ্য, লেখার সামগ্রী, কার্টন বাক্স এবং খেলার সরঞ্জাম অন্তর্ভুক্ত। এর সমন্বয়যোগ্য চাকা সিট এবং চাপ সিস্টেম বিভিন্ন উপকরণ এবং পৃষ্ঠের জন্য সমানভাবে আঠালো প্রয়োগ করতে সক্ষম।

হট মেল্ট আঠালো ট্রফটিকে টেফলন দিয়ে প্রক্রিয়া করা হয়, আঠালো উপকরণের প্রতিস্থাপনকে সহজ করে তোলে। আঠালোর বৈশিষ্ট্য অনুযায়ী তাপমাত্রা সমন্বয় করা যেতে পারে, উৎপাদনের সময় কার্বনাইজেশন এড়াতে কার্যকরভাবে সাহায্য করে। নিরাপত্তা এবং স্থায়িত্বের জন্য, মোটরটিতে একটি তাপীয় সুরক্ষা যন্ত্র রয়েছে এবং মেশিনটিতে গন্ধ নির্গমনের জন্য একটি নির্গমন ব্যবস্থা রয়েছে।

মটরটি ফ্রিকোয়েন্সি কনভার্সন স্পিড নিয়ন্ত্রণ ব্যবহার করে যা নিরবিচ্ছিন্ন গতি সমন্বয় করতে সক্ষম, বিভিন্ন উৎপাদন প্রয়োজনীয়তা মেটানোর জন্য অনুকূলিত হয়। জরুরি বোতামটি চাপ দেওয়ার সময় মটরের অপারেশন পিছনের দিকে চালিত হয় যাতে সুরক্ষিতভাবে উপকরণসমূহ ফিরিয়ে আনা যায় এবং অপারেটরের নিরাপত্তা নিশ্চিত হয়।