Guangdong Tenghong Machinery Technology Co., Ltd. est un fabricant leader spécialisé dans les machines pour la production de chaussures. Forte d'une vaste expérience industrielle, l'entreprise développe des équipements hydrauliques avancés pour l'assemblage de semelles, qui permettent une fabrication automatisée de semelles enveloppées.

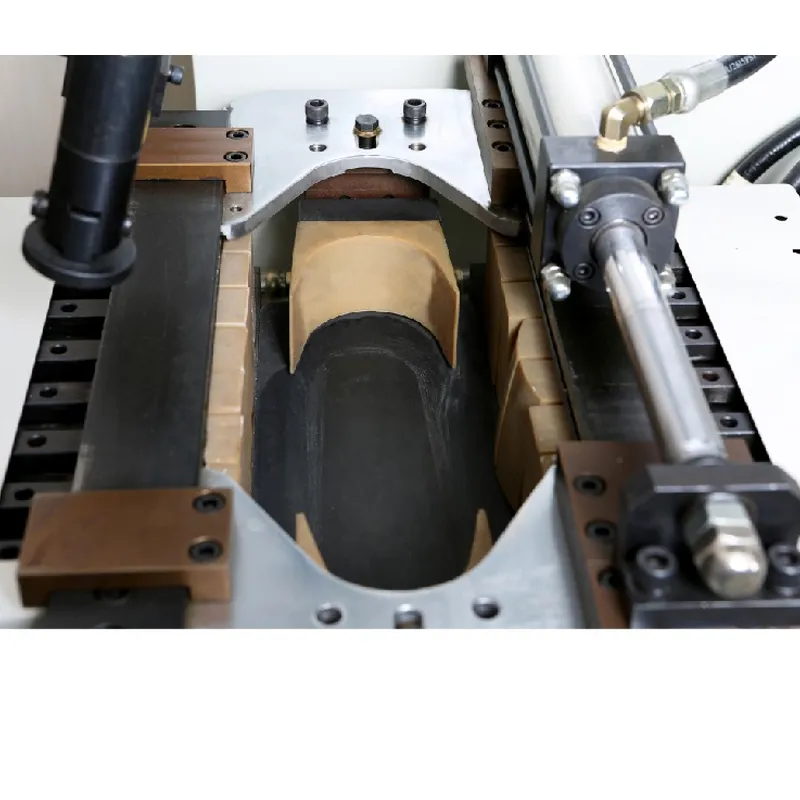

La machine supporte une large gamme de dimensions pour les formes et les semelles de chaussures, assurant un collage précis et constant pour les semelles épaisses. Les multiples points de pression permettent un pressage indépendant ou simultané sur la semelle inférieure et les bords. Son système hydraulique fournit une force puissante et constante, garantissant une adhérence durable et réduisant les défaillances produits. Compacte et pesant environ 430 kg, elle s'intègre parfaitement aux lignes de production existantes pour accroître l'efficacité de l'usine.

Tenghong Machinery est reconnu pour son innovation, son contrôle qualité et son excellent service client, aidant les usines de chaussures à optimiser leur production et à maintenir des normes de produits compétitives.