Guangdong Tenghong Machinery Technology Co., Ltd., established in 2000 in Houjie, Dongguan, is a leading provider of both modern and legacy shoe making equipment. Tenghong specializes in supplying complete solutions for B2B footwear production, covering cutting, stitching, pasting, sole attaching, riveting, eyeleting, steam forming, and finishing equipment. While the company develops advanced CNC-controlled machines with IoT integration, it also offers robust old shoe making equipment for factories seeking cost-effective, durable, and flexible production solutions.

With a skilled team of over 150 industry experts, Tenghong ensures all machines, whether modern or legacy, meet high standards of reliability and precision. The company provides comprehensive services including pre-sale planning, installation, operator training, commissioning, and after-sales maintenance. Tenghong machines are CE-certified and ISO9001:2008 compliant, supporting multi-material shoe production from leather and synthetics to textiles and rubber. This enables B2B factories to produce a wide variety of footwear, including casual shoes, athletic shoes, boots, safety shoes, and medical footwear.

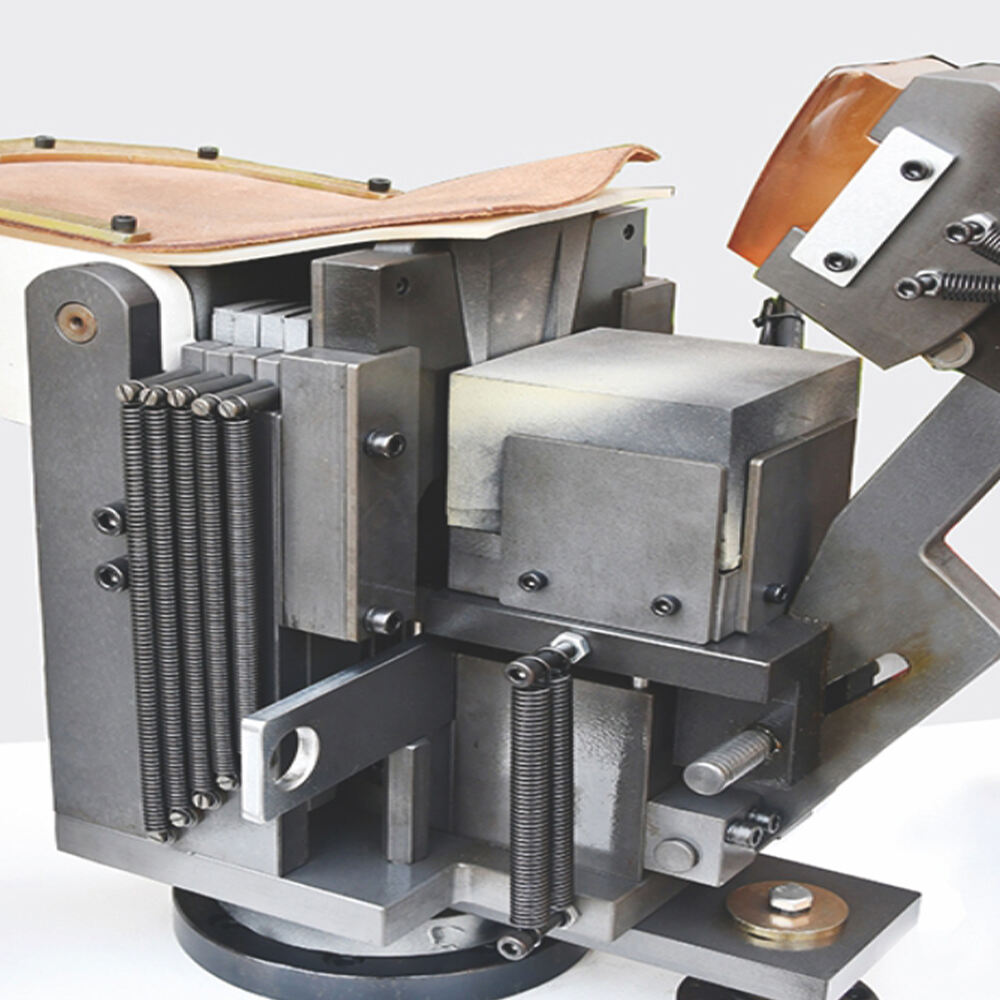

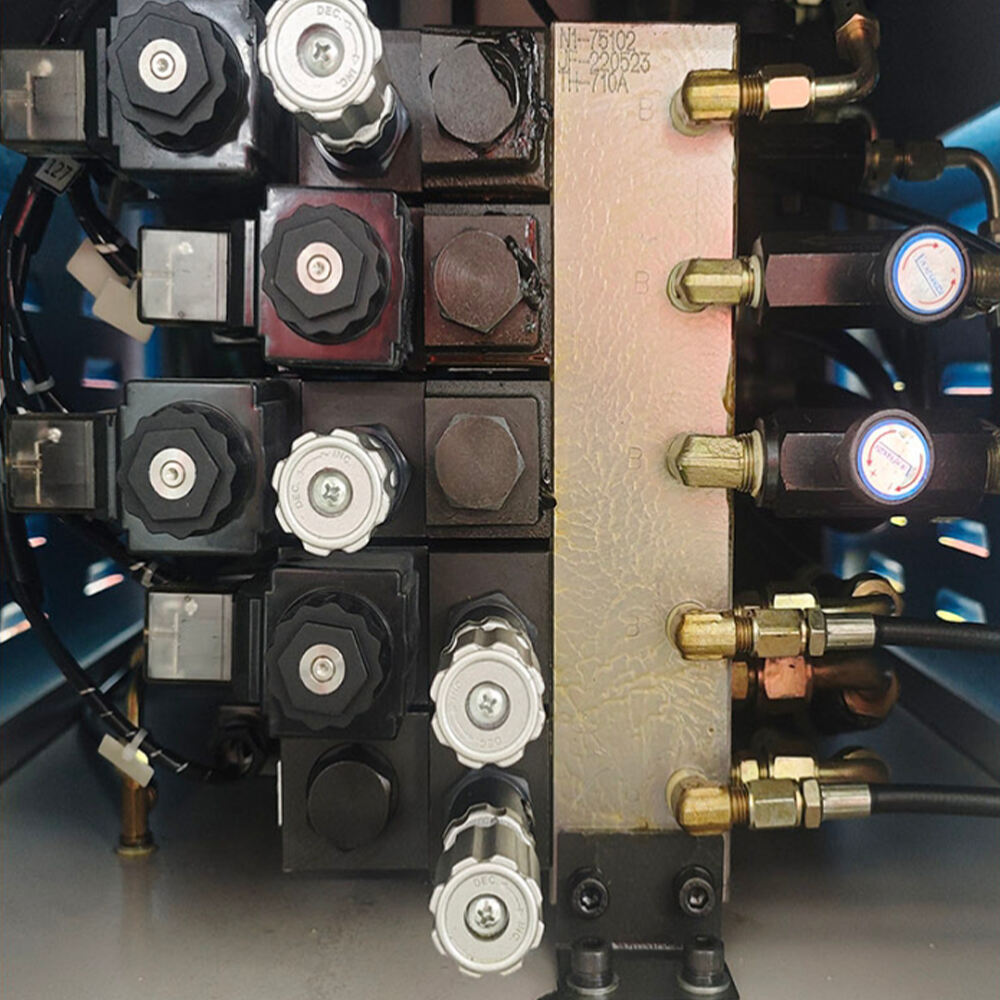

Legacy machines are valued for their durable construction, stable operation, and low maintenance needs. Tenghong offers retrofit options to integrate partial automation, digital monitoring, and enhanced safety features into these older machines, providing a cost-effective way to modernize production lines. The company’s modular design philosophy allows machines to be upgraded with additional functions or customized tooling to suit specialized production.

Tenghong’s corporate culture emphasizes teamwork, innovation, and customer satisfaction. Collaboration between R&D, production, and service teams ensures clients receive tailored guidance, from equipment selection to installation and ongoing technical support. Remote monitoring, predictive maintenance, and global spare parts supply enhance operational reliability. These capabilities enable B2B shoe factories to maintain competitive production, balance capital investment, and achieve high-quality output with both modern and legacy equipment. Tenghong’s commitment to long-term value and operational excellence positions it as a trusted partner for global footwear manufacturers.