Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 in Houjie, Dongguan, is a leading manufacturer of high-tech footwear machinery, including specialized solutions for plastic shoe production. Tenghong serves B2B factories worldwide, providing automated, semi-automated, and manual machines for EVA, PVC, TPR, and other thermoplastic footwear. With over 20 years of experience, the company supports small-scale workshops and large-scale export factories, delivering efficient, reliable, and durable machinery.

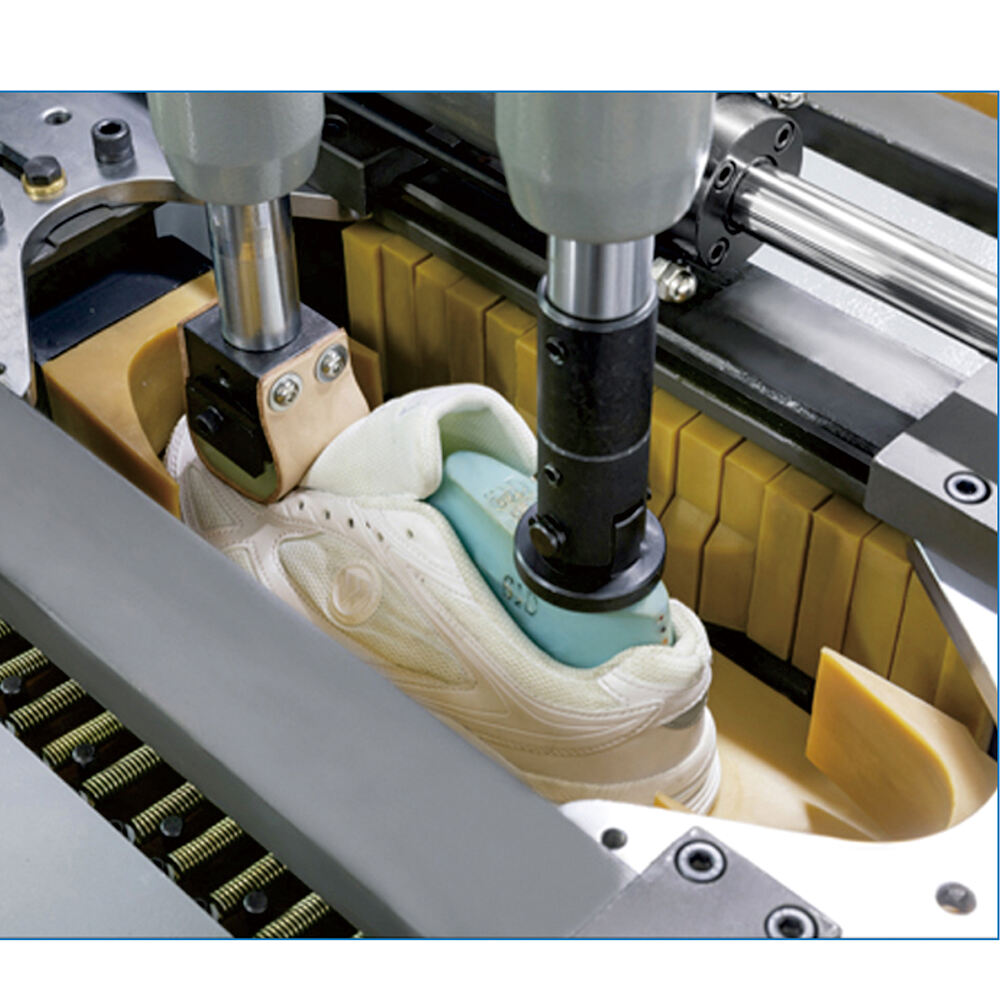

The company’s product line includes plastic shoe making machines, cutting equipment, punching machines, sole pasting systems, and multi-function combination machines. These solutions are designed for precise molding, automated feeding, and consistent assembly across multiple shoe types. Tenghong employs over 150 engineers and technical staff who provide pre-sale consultation, installation, operator training, commissioning, and after-sales service to optimize machine performance and production efficiency.

All Tenghong machinery complies with ISO9001:2008 and CE certification standards, meeting international quality, safety, and environmental requirements. The plastic shoe making machine features PLC-controlled operation, automated feeding, modular molds, and intelligent temperature management, ensuring high-quality thermoplastic footwear production. IoT integration allows real-time monitoring, predictive maintenance, and performance tracking.

Tenghong’s corporate culture emphasizes innovation, teamwork, and customer satisfaction. By combining advanced technology with expert R&D, Tenghong helps B2B factories streamline production, reduce labor costs, and maintain consistent export-quality standards. Long-term partnerships in Southeast Asia, Europe, and the Middle East reflect the company’s commitment to reliable, high-performance machinery and comprehensive global support for footwear manufacturers.