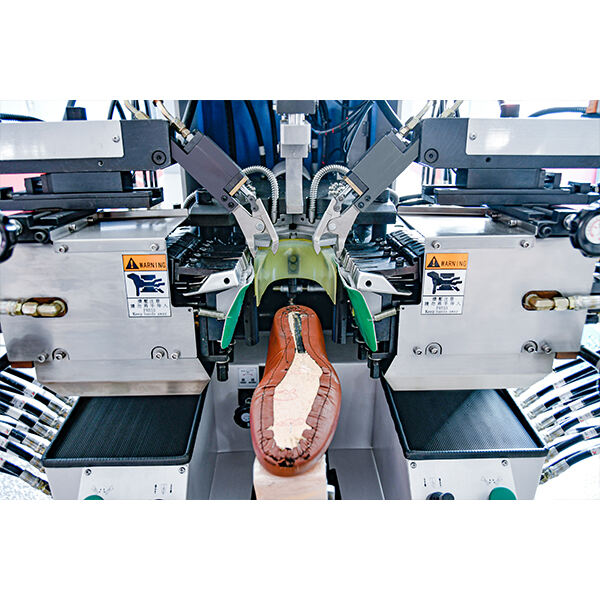

Guangdong Tenghong Machinery Technology Co., Ltd., established in 2000, is a leader in manufacturing advanced shoe production equipment, including casual shoe machines. With headquarters in Dongguan, the company brings together more than 150 skilled engineers and technicians, creating innovative machinery with ISO9001 certification and CE approval. Tenghong’s solutions integrate CNC systems, robotics, and IIoT capabilities to deliver precise, reliable, and energy-efficient equipment. Beyond production, the company offers full lifecycle support: pre-sales consultation, installation, operator training, maintenance, and spare parts services. With strong global reach, Tenghong helps factories increase efficiency, reduce labor dependency, and achieve consistent quality in casual shoe manufacturing.

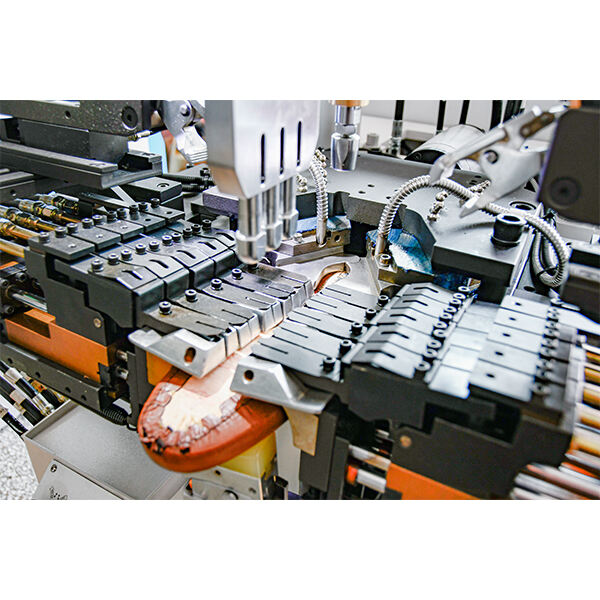

Tenghong integrates advanced automation features into all its machines, such as PLC-controlled operations, vacuum-assisted material positioning, multi-point pressure control, and automated mold change systems. Intelligent monitoring, real-time error detection, and remote diagnostics allow factories to maintain optimal production output while reducing downtime and operational risks, ensuring consistent quality and reliability for B2B operations.