Guangdong Tenghong Machinery Technology Co., Ltd. represents the capabilities of a modern China shoemaking machinery factory. Founded in 2000 in Houjie, Dongguan, Tenghong has grown into a leading manufacturer specializing in shoe and bag machinery. The company integrates advanced R&D, large-scale production, and international service, supplying high-performance machinery to global footwear brands.

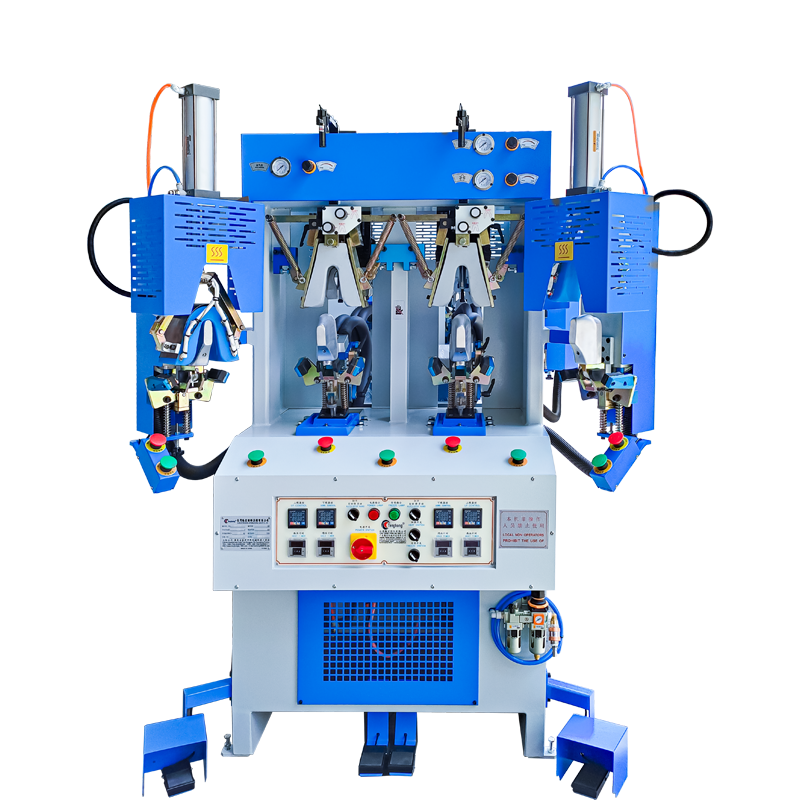

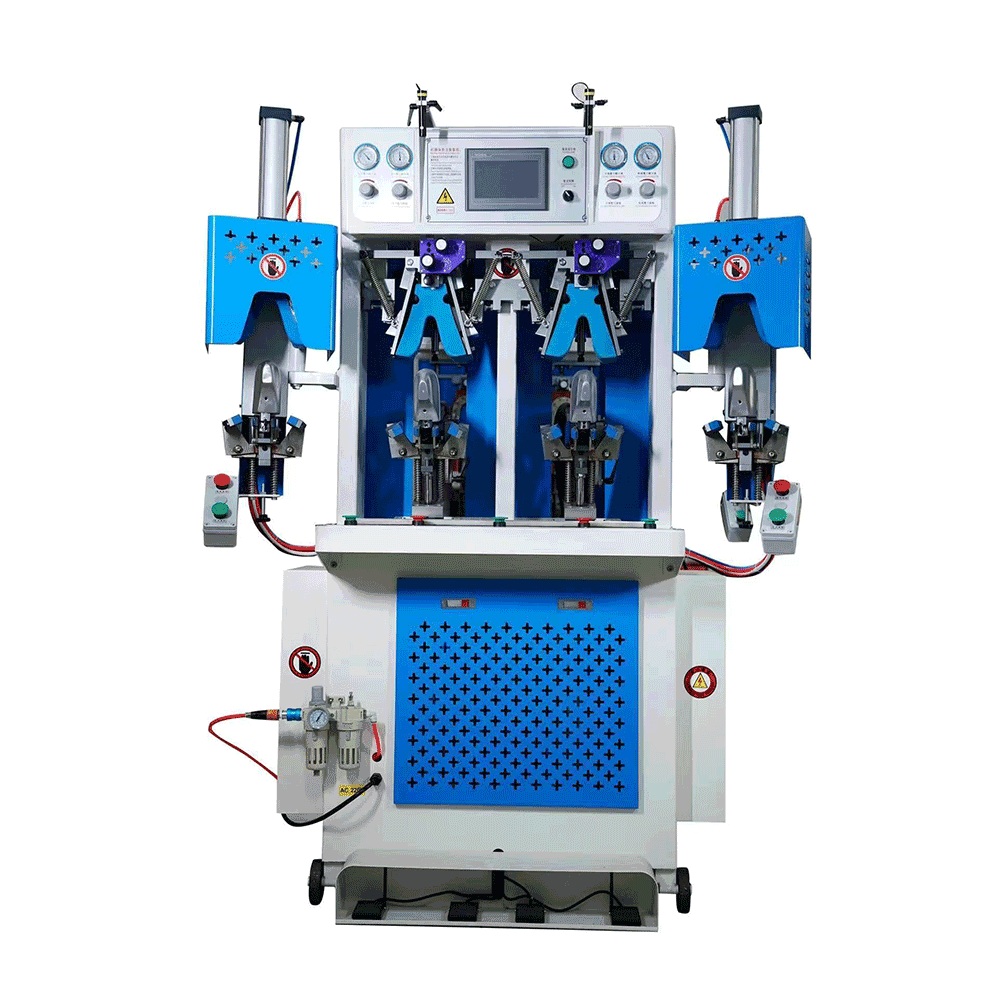

As a China shoemaking machinery factory, Tenghong focuses on combining technological innovation with robust engineering. Its product portfolio includes shoemaking production lines, sole attaching machines, upper crimping systems, and multi-functional equipment tailored for sports shoes, leather footwear, and industrial boots. Every machine undergoes rigorous testing to comply with CE certification and ISO9001 standards, ensuring buyers receive equipment that meets global benchmarks.

The company’s strength lies in its talented workforce of more than 150 professionals, including engineers, technicians, and support staff. This team collaborates closely to deliver customized solutions, integrating automation, precision, and energy efficiency into every project. Tenghong invests heavily in advanced CNC machining, assembly facilities, and quality control laboratories, reinforcing its position as a trusted China shoemaking machinery factory.

Beyond manufacturing, Tenghong provides complete lifecycle services. From pre-sale consulting and layout planning to on-site installation, operator training, and long-term maintenance, Tenghong ensures smooth operation for B2B buyers. A global spare parts supply chain and remote troubleshooting services further enhance reliability.

Sustainability is also a core priority. Tenghong integrates eco-friendly lubricants, recyclable materials, energy-saving motors, and low-emission processes into its machinery. By doing so, it reduces both operational costs and environmental impact, aligning with global industry trends.

Over the years, Tenghong has built a strong global reputation, exporting to Southeast Asia, Europe, the Middle East, and beyond. Its machines deliver high ROI by lowering production costs, reducing downtime, and enabling scalable operations. For B2B clients, choosing a China shoemaking machinery factory like Tenghong means more than purchasing equipment—it means partnering with a company dedicated to continuous innovation, reliability, and shared success.