Shoe sole press machine pricing reflects various factors including machine capacity, technology level, and additional features. Guangdong Tenghong Machinery Technology Co., LTD., established in 2000 in Dongguan city—a famed shoe manufacturing hub—has developed an extensive product line including advanced hydraulic sole attaching machines like the TH-710E. This model is a prime example of how the company fuses top-grade components with innovative design to deliver performance and value.

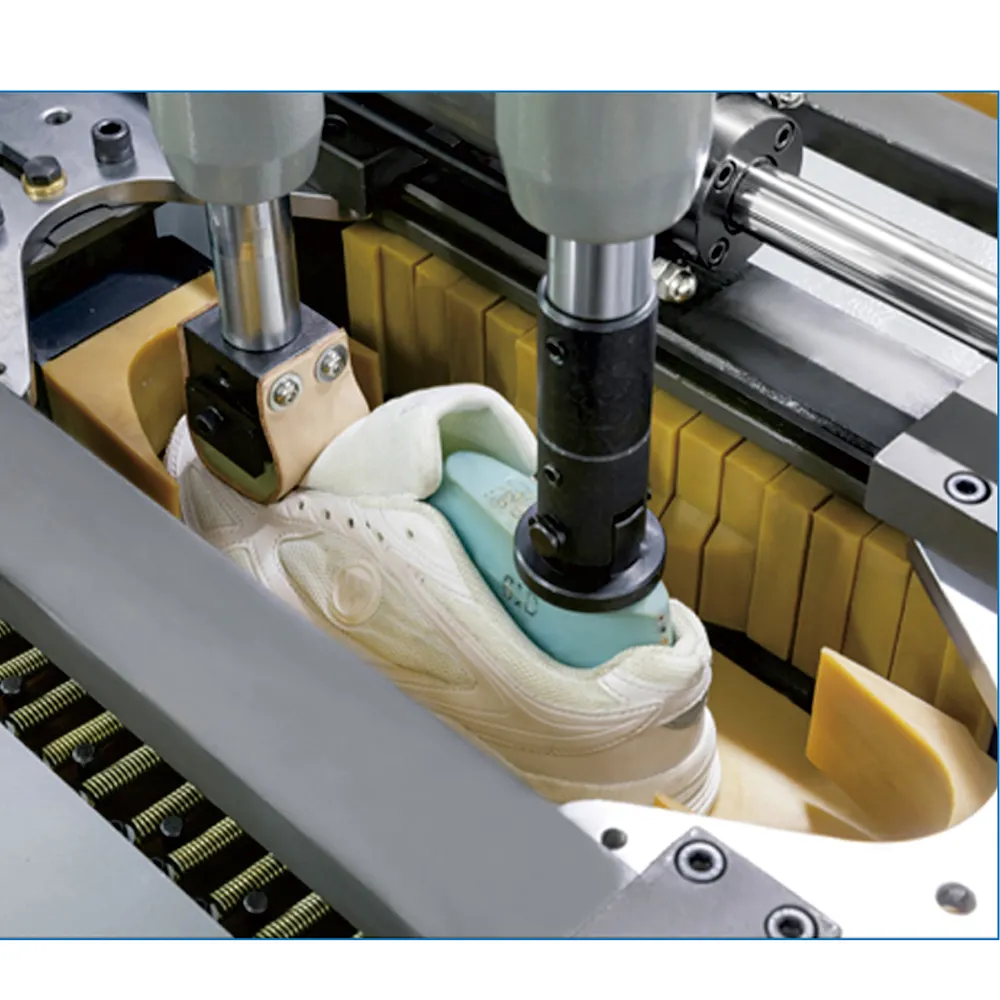

The TH-710E features a 1.5 kW hydraulic pump generating oil pressure of 50 kg/m3 which powers the heavy-duty pressing mechanism. It weighs 629 kg and fits comfortably within a factory footprint of 105 by 80 by 192 centimeters. This robust design supports double-station operations to enhance output capacity and supports automatic heel adjustments for both male and female shoes of varying sizes and heel heights. This makes the machine suitable for diverse footwear from casual to formal styles requiring durable sole adhesion.

The company’s commitment to ISO9001:2008 quality standards and continuous technological improvements ensures that their machines, including those priced competitively, meet international certifications and customer expectations. Tenghong also offers clients pre-sale plant planning, installation, and after-sales technical support to maximize machine uptime and production efficiency.

Shoe manufacturers targeting high output, solid adherence, and cost-efficient sourcing will find this shoe sole press machine price attractive given its performance and reliability. The combination of double stations, adjustable pressing grades, and strong oil pressure delivers excellent value for businesses aiming to expand and upgrade production lines.