Guangdong Tenghong Machinery Technology Co., Ltd. is a trusted manufacturer specializing in high-tech shoemaking and leather goods machinery since 2000. Based in Houjie, Dongguan, the company has established itself as a global leader in the production and supply of advanced footwear manufacturing equipment. Over the past two decades, Tenghong has consistently focused on innovation, precision engineering, and customer-driven solutions, making it a reliable partner for shoe factories and industrial equipment buyers worldwide.

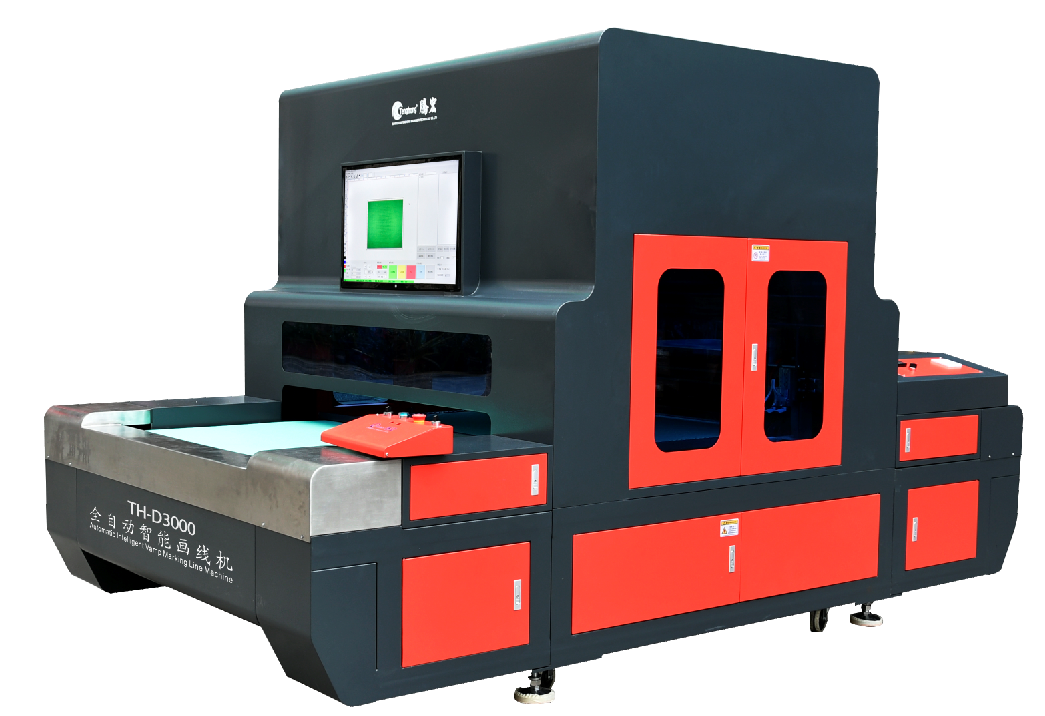

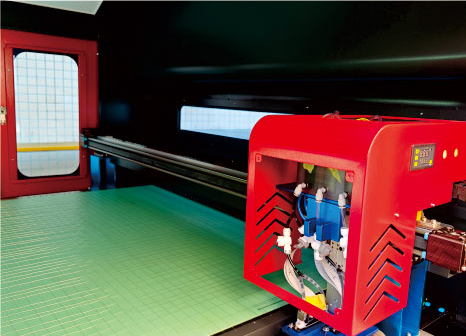

The company’s diverse product portfolio includes dyeing machines, lasting machines, cutting equipment, sewing solutions, and fully automated production lines. Each machine is designed with a focus on productivity, cost efficiency, and durability, enabling clients to achieve higher throughput and consistent product quality. With CE-certified equipment and ISO9001:2008 quality management compliance, Tenghong ensures that every product meets international safety and performance standards.

One of Tenghong’s greatest strengths lies in its team of over 150 industry experts, including R&D engineers, production specialists, and customer service professionals. This elite workforce allows the company to deliver comprehensive services covering pre-sales consultation, customized production planning, on-site installation, commissioning, and long-term after-sales support. Clients benefit from Tenghong’s ability to provide both standard machinery and tailored solutions to meet specific production needs.

Tenghong fosters a corporate culture centered on innovation, quality, and mutual growth. By integrating advanced technologies such as CNC precision machining, industrial IoT compatibility, and digital process control, the company continuously develops new solutions aligned with Industry 4.0 standards. Its mission is to help shoe factories reduce costs, improve efficiency, and achieve long-term sustainable development.

With an extensive export network covering Southeast Asia, Europe, and beyond, Tenghong Machinery has built strong global partnerships. Its competitive edge lies not only in high-quality machines but also in a reliable supply chain for spare parts, technical training programs, and responsive local service teams. As the footwear industry evolves, Guangdong Tenghong Machinery Technology Co., Ltd. remains committed to delivering practical, advanced, and cost-effective equipment, ensuring customer success in a competitive global market.