Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 in Houjie, Dongguan, has become a global leader in designing and manufacturing advanced footwear machinery. For more than twenty years, Tenghong has focused on delivering high-quality, high-speed, and customizable solutions that address the evolving needs of footwear factories worldwide.

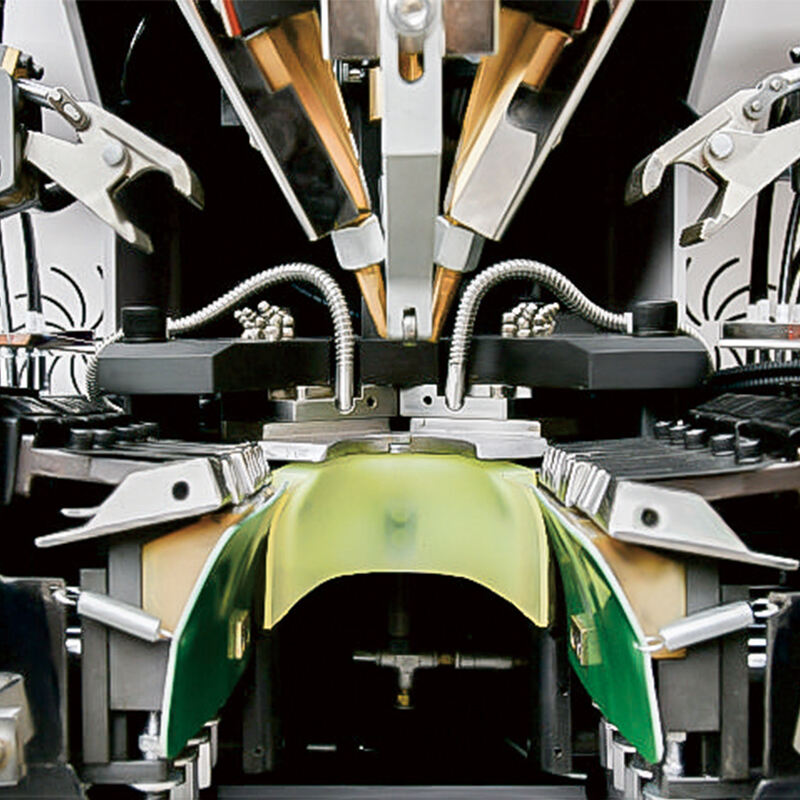

Tenghong specializes in CNC cutting machines, automated stitching systems, gluing and sole injection units, and fully integrated production lines. The high speed shoe machine is specifically designed to maximize output for large-scale operations, incorporating robotics, multi-axis control, and machine vision for precise, repeatable performance. Its modular design ensures flexibility for multiple shoe styles, sizes, and materials. By optimizing workflow integration and cycle times, factories achieve higher throughput and improved operational efficiency.

All Tenghong machinery complies with ISO9001 quality standards and holds CE certification, ensuring global safety, performance, and reliability. The company’s R&D team of over 150 experts continuously innovates, incorporating IIoT technology for real-time monitoring, predictive maintenance, and automated quality inspections. This ensures that high-speed machines operate smoothly in multi-shift environments while minimizing downtime, energy consumption, and maintenance costs.

Beyond manufacturing, Tenghong offers comprehensive lifecycle services, including pre-sale planning, factory layout optimization, equipment installation, commissioning, operator training, and ongoing maintenance. Remote monitoring and global spare parts support ensure factories remain operational at all times. Tenghong’s culture emphasizes innovation, teamwork, and customer satisfaction, fostering long-term partnerships and delivering equipment that meets high-volume production goals while maintaining consistent quality.

With a strong presence in Southeast Asia, Europe, and other international markets, Tenghong is recognized for producing reliable, high-speed footwear machinery that combines efficiency, precision, and sustainability. The company’s dedication to innovation and quality ensures that manufacturers can accelerate production while minimizing operational costs and environmental impact, making it a preferred partner for large-scale, high-performance footwear factories worldwide.