Guangdong Tenghong Machinery Technology Co., Ltd., established in 2000 in Houjie, Dongguan, is a leading manufacturer of high-tech footwear machinery. The company specializes in producing, selling, and servicing advanced shoe production machines, including shoe upper machines, sole attaching equipment, and automated finishing systems. With over 150 skilled professionals, Tenghong combines research, production, and customer service into a comprehensive B2B solution for footwear factories worldwide.

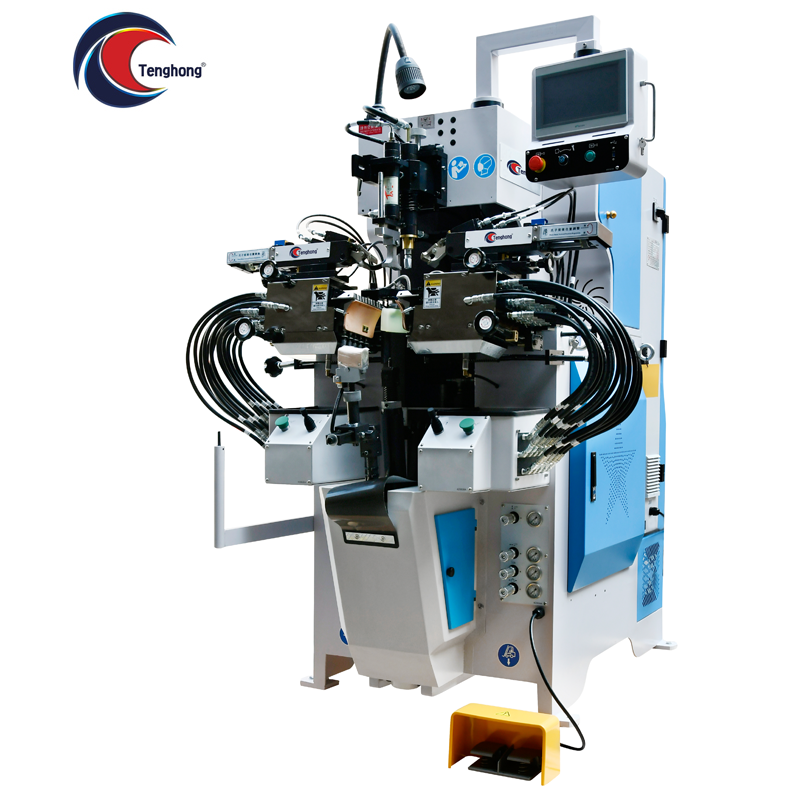

The company emphasizes innovation, automation, and precision. Its shoe upper machines feature CNC-controlled stitching, high-speed feeding systems, and laser-guided alignment to guarantee high-quality output and consistency. Modular designs and multi-function capabilities allow factories to adapt production lines for diverse footwear types, from sports shoes to leather boots and safety footwear. Tenghong machinery is CE-certified and ISO9001:2008 compliant, reflecting strict quality standards and international market readiness.

Tenghong also offers complete support services, including pre-sale planning, installation, operator training, debugging, and after-sales maintenance. Its global spare parts network ensures quick response and minimal downtime, while digital monitoring and predictive maintenance tools reduce operational risk. Factories benefit from turnkey solutions that improve workflow efficiency, product quality, and scalability.

In addition to technology and service, Tenghong values sustainability. Its machinery integrates energy-efficient motors, low-waste material handling, and environmentally friendly consumables, aligning with modern manufacturing demands. The company culture prioritizes innovation, collaboration, and customer satisfaction, fostering continuous improvement and the development of cost-effective, durable, and high-performance footwear machinery.

By combining advanced engineering, reliable service, and flexible production solutions, Tenghong has become a trusted partner for global footwear manufacturers seeking efficient and scalable production capabilities. Its shoe upper machines exemplify the company’s commitment to precision, automation, and adaptability, helping B2B clients optimize their operations and maintain competitive advantage in international markets.