Sole pressing is a pivotal step in footwear production, affecting product durability and overall quality. Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 and based in Dongguan’s specialized shoemaking hub, has emerged as a leader in innovative shoe machinery solutions with a professional team of over 150 experts. The company offers a wide array of products including toe lasting machines, hydraulic heel-lasting units, heavy-duty sole attaching machines, and smart servo-controlled systems, globally recognized in the footwear industry.

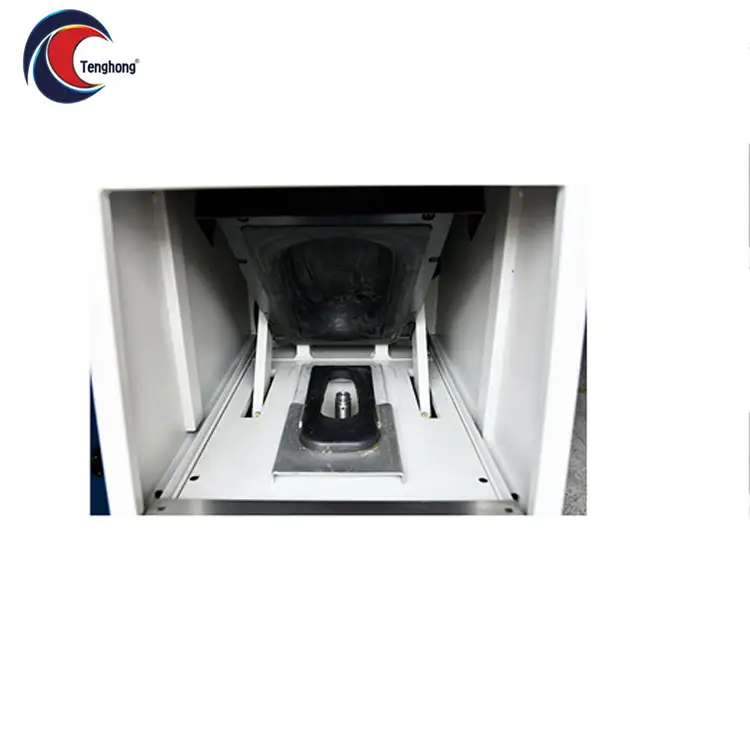

The Tenghong TH586A pneumatic sole attaching machine exemplifies state-of-the-art technology and user-focused design. Featuring dual pneumatic cylinders, the machine alternates pressures to pack the sole into place and then firmly press it against the shoe upper to secure bonding. This dual-pressure approach eliminates bubbles, wrinkles, and weak adhesion points. Its adjustable shoe height accommodates diverse footwear forms, preventing damage during processing and enabling compatibility with various shoe sizes and styles.

The machine supports both manual and automatic operation modes. Beginners can safely operate the press manually, while automatic mode allows experienced workers to maintain a steady production flow with minimal downtime. Its user-friendly interface and reliable control system facilitate fast cycle times, increasing production efficiency to 1500 pairs per 8 hours. The machine is particularly effective for sport shoes, leisure footwear, and any designs featuring large, smooth soles demanding strong adhesion.

Guangdong Tenghong Machinery complements its superior products with comprehensive customer support including installation, commissioning, operator training, and responsive after-sales service. Their commitment to quality and innovation empowers customers to enhance manufacturing quality, capacity, and competitiveness in the dynamic global footwear market.