Guangdong Tenghong Machinery Technology Co., Ltd., headquartered in Houjie, Dongguan, is a leading manufacturer of professional shoemaking and leather machinery. Established in 2000, the company has become one of China’s most trusted suppliers of innovative footwear production solutions. With more than 20 years of experience, Tenghong specializes in designing and producing equipment that enhances efficiency, precision, and profitability for footwear factories worldwide.

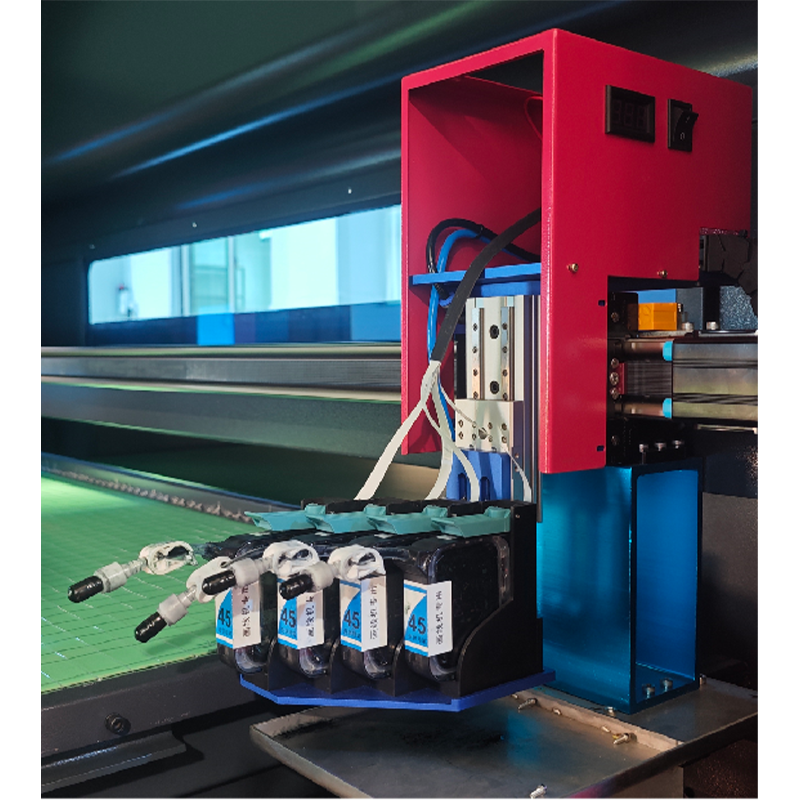

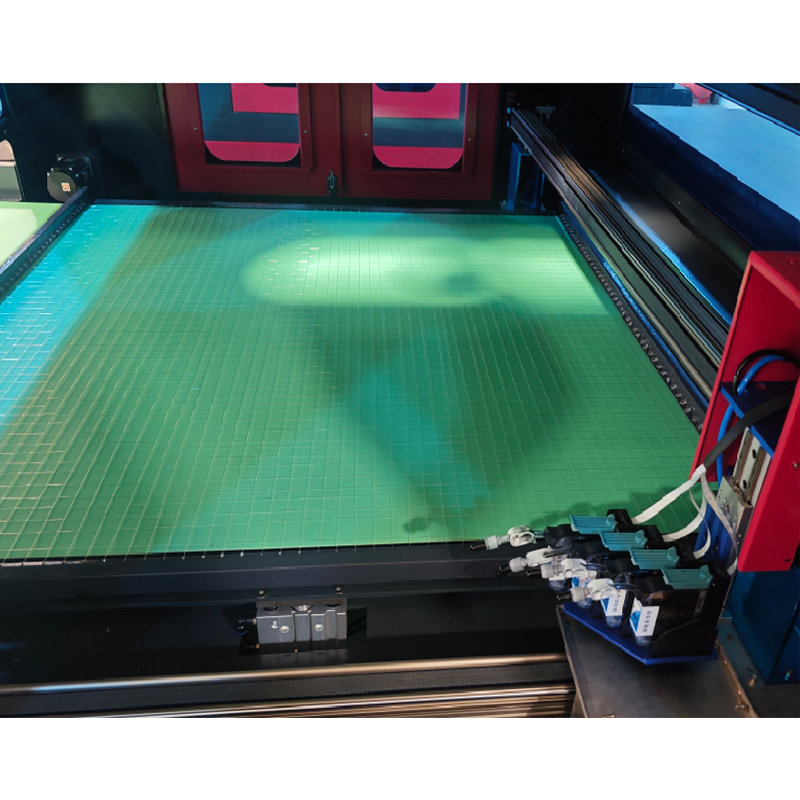

The company’s product line includes toe steaming machines, lasting equipment, eyelet punching machines, cutting systems, and fully automated shoemaking lines. Each machine is built using advanced CNC machining technology, precision engineering, and strict ISO9001:2008 quality control standards. As a result, every unit produced by Tenghong meets global certification requirements such as CE, ensuring safety, durability, and reliability in industrial applications.

Tenghong’s competitive advantage lies in its integrated R&D and customer service teams. Over 150 skilled professionals, including mechanical engineers, technicians, and project managers, collaborate to design innovative solutions aligned with modern footwear manufacturing demands. This enables Tenghong to not only deliver standardized machines but also provide customized solutions tailored to specific factory workflows and product lines.

The company also emphasizes customer success through comprehensive service. From pre-sales consultation and equipment planning to installation, operator training, and long-term technical support, Tenghong maintains a commitment to ensuring smooth adoption and operation of its machines. Its global after-sales network provides spare parts, on-site servicing, and remote troubleshooting to minimize downtime for factories.

Tenghong’s mission is to empower footwear manufacturers with high-quality, efficient, and sustainable machinery. By integrating modern automation technologies, energy-efficient systems, and user-friendly designs, Tenghong continuously supports its clients in scaling production, lowering costs, and meeting competitive market demands. Today, Tenghong Machinery exports to Southeast Asia, Europe, and beyond, serving as a trusted partner for thousands of shoe factories seeking long-term growth.