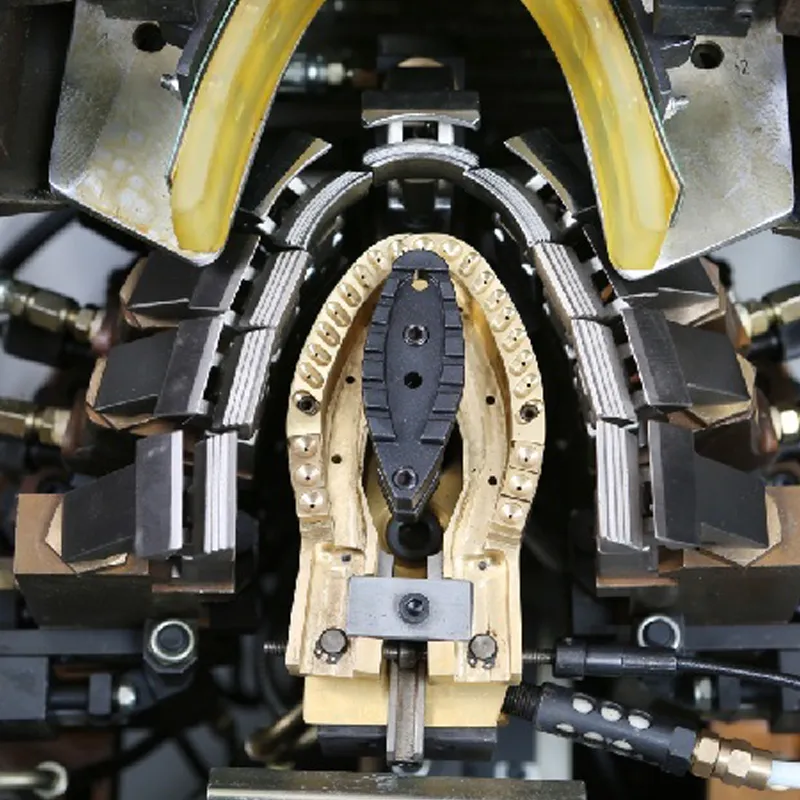

This machine uses a robust oil pressure system to provide stable and precise operation during toe lasting. Its intelligent PLC control with touch screen enables users to enter stroke and timing parameters easily and lock the settings for safety. Equipped with nine multifunctional pincers that allow 15-degree lateral deflections and automatic rotations, the device achieves optimal vamp lasting for a variety of shoe models. The inner support table and press head have adjustable and two-stage press mechanisms to maintain consistent pressure. The system can save up to 100 shoe pattern parameters for quick transitions across models. An automatic glue feeding and precision application mechanism greatly reduces labor and enhances production efficiency, making this machine a key asset for modern intelligent footwear production lines.