Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 in Dongguan, specializes in designing and manufacturing advanced footwear machinery, including safety shoe making machines. With over two decades of experience, Tenghong is recognized for delivering high-quality, reliable solutions for both domestic and international footwear manufacturers.

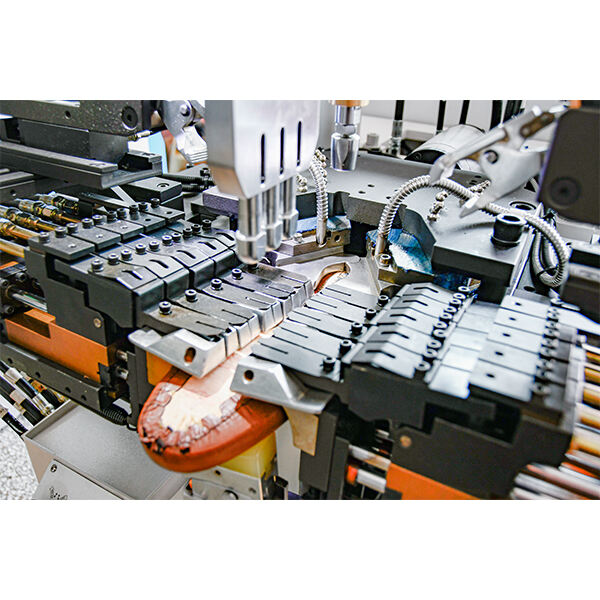

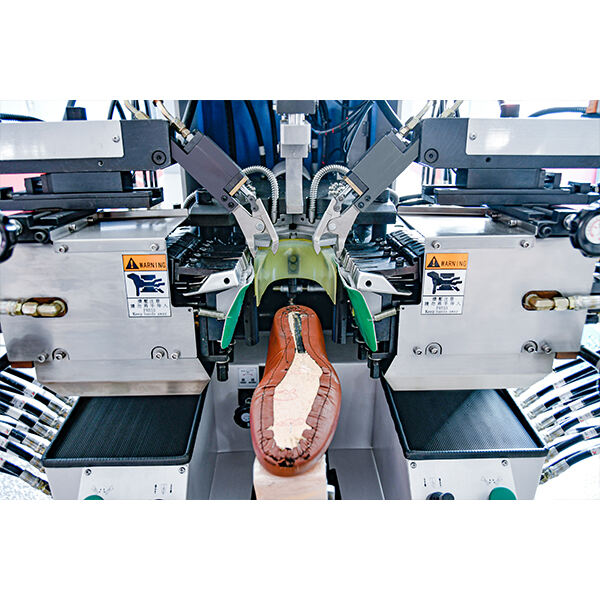

The safety shoe making machine exemplifies Tenghong’s dedication to precision, automation, and safety. It integrates cutting, molding, toe reinforcement, sole assembly, and finishing in one automated line. Compatible with steel-toe, composite-toe, and anti-slip shoes, the machine ensures consistent quality across all protective footwear types. Adjustable pressure, automatic feeding, and PLC controls provide flexibility, allowing manufacturers to process multiple models without additional equipment.

Tenghong maintains strict quality assurance under ISO9001 standards, and all machines are CE-certified for international safety compliance. Each safety shoe making machine undergoes rigorous testing, including load-bearing tests, accuracy checks, and operational simulations. This ensures reliable performance in high-volume, industrial environments.

In addition to machinery, Tenghong provides comprehensive services: pre-sale consultation, installation, operator training, and after-sales maintenance. IoT monitoring, remote diagnostics, and software upgrades optimize long-term machine performance.

With a professional team of over 150 R&D engineers and technicians, Tenghong continues to innovate in footwear machinery. Its global footprint spans Southeast Asia, Europe, and Latin America, supplying factories with high-efficiency safety shoe making machines. Tenghong’s mission, “mutual benefit and ideal achievements,” guides continuous improvement, ensuring customers receive equipment that combines productivity, safety, and long-term reliability.