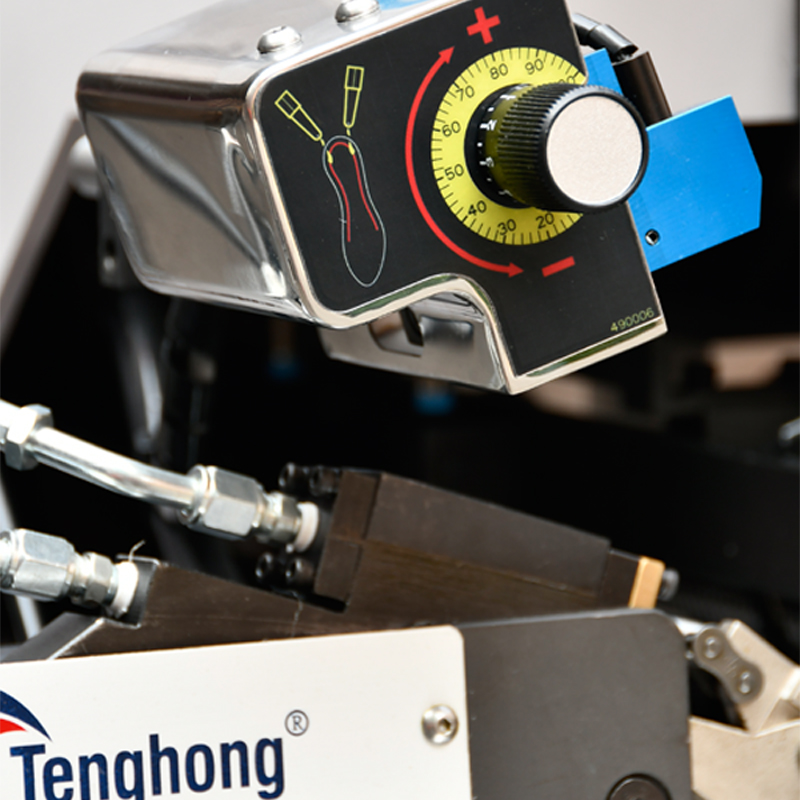

Guangdong Tenghong Machinery Technology Co., Ltd., established in 2000 in Houjie, Dongguan, is a globally recognized manufacturer specializing in advanced footwear machinery. Over more than twenty years, Tenghong has focused on delivering high-performance, automated solutions that address the evolving requirements of modern shoe factories.

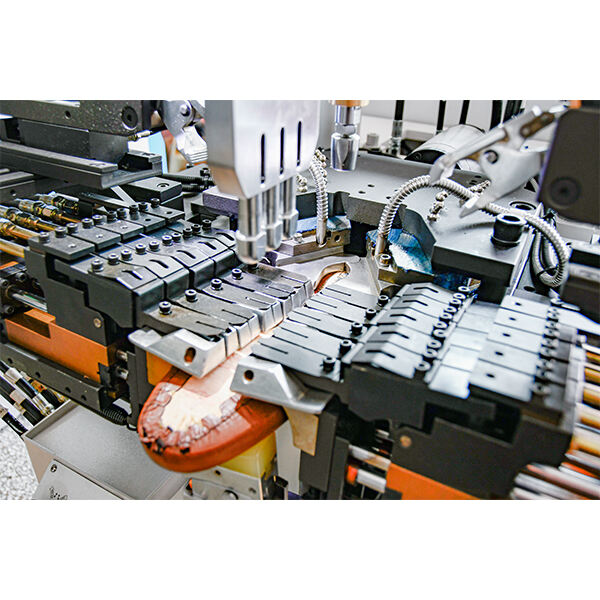

The company’s portfolio includes CNC cutting machines, automated stitching systems, gluing and finishing units, sole injection machines, and integrated production lines. These solutions enable factories to produce high-quality footwear efficiently, maintain consistent product standards, and scale operations effectively. With multi-axis robotics, machine vision, and IIoT-enabled monitoring, Tenghong ensures precise alignment, real-time defect detection, and predictive maintenance capabilities across all production processes. Modular and programmable designs provide adaptability for diverse shoe styles, sizes, and materials, including leather, textile, and synthetic composites, allowing rapid switching between models without downtime.

Tenghong’s ISO9001 certification and CE compliance guarantee global safety and quality standards. The company maintains a highly skilled team of over 150 engineers who continuously innovate and integrate advanced technologies such as robotic automation, IIoT monitoring, and automated quality control. These capabilities maximize throughput, reduce energy consumption, minimize waste, and ensure multi-shift production consistency for high-volume operations.

Comprehensive services are a core strength of Tenghong. Pre-sale planning includes factory layout design, workflow optimization, and product consultation. Post-sale services cover equipment installation, commissioning, operator training, maintenance, and remote technical support. Rapid spare parts delivery and long-term system updates further enhance operational reliability.

Tenghong fosters a corporate culture emphasizing innovation, collaboration, and customer satisfaction. The company’s philosophy of “mutual benefit and ideal achievement” drives a commitment to delivering efficient, cost-effective, and high-quality footwear machinery. Recognized internationally in Southeast Asia, Europe, and other regions, Tenghong continues to provide large-scale factories with reliable, precise, and efficient solutions that meet the growing global demand for high-quality footwear.