Guangdong Tenghong Machinery Technology Co., Ltd., established in 2000 in Houjie, Dongguan, is a leading supplier of high-tech footwear machinery, including pasting, upper assembly, and finishing equipment. The company specializes in B2B solutions for factories producing athletic shoes, safety footwear, leather shoes, and boots.

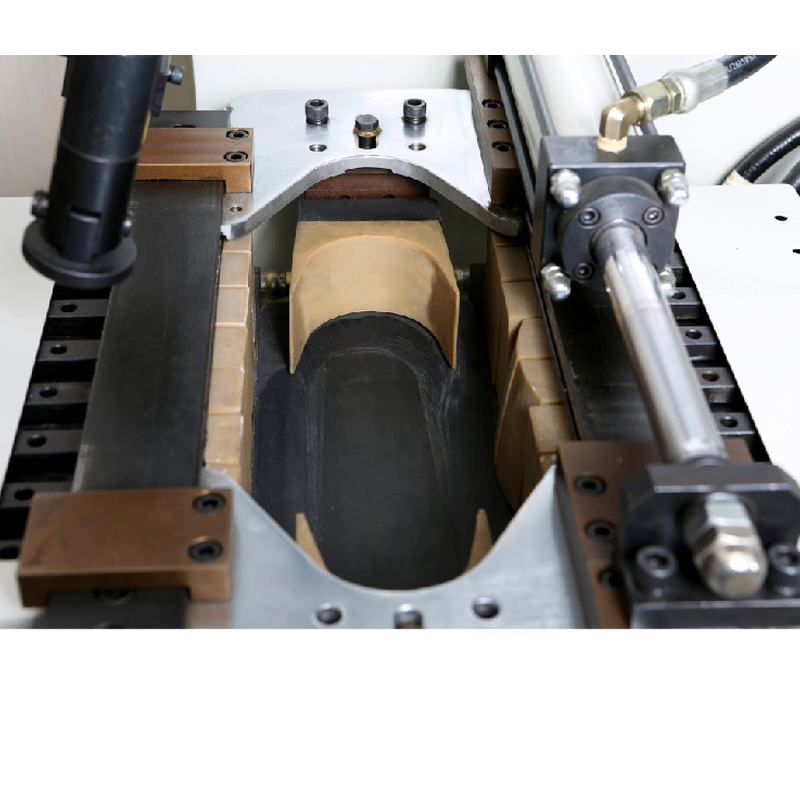

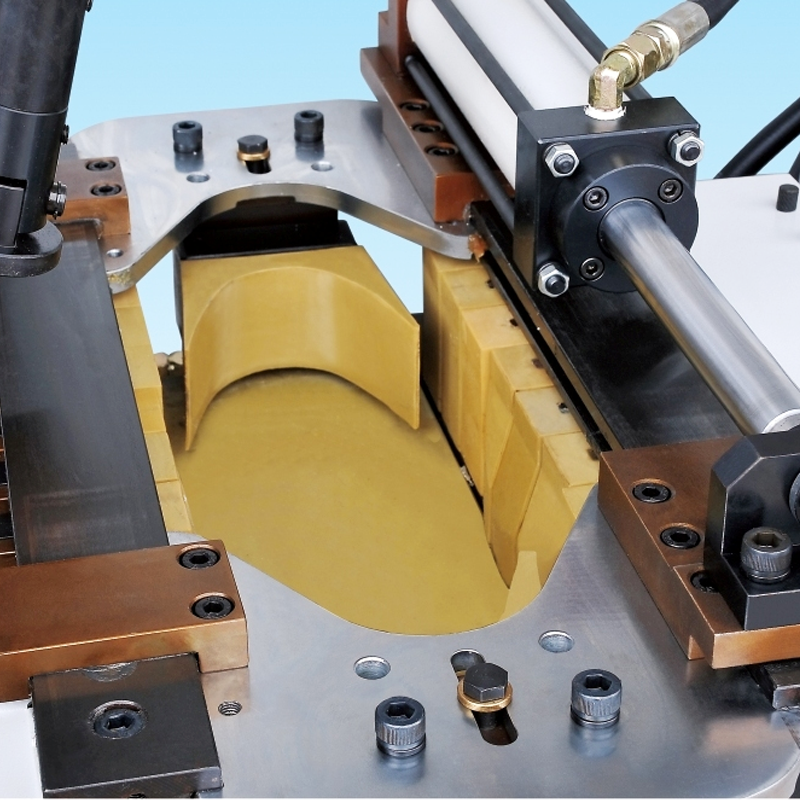

Tenghong combines over 20 years of expertise with a top-tier R&D and production team of more than 150 professionals. Its footwear pasting machines feature automated feeding, CNC glue application, precise temperature control, and modular tooling to ensure accurate and consistent bonding across diverse shoe types and materials. CE-certified and ISO9001:2008 compliant, Tenghong equipment meets international standards and is exported worldwide.

The company provides comprehensive services, including pre-sale consultation, factory planning, installation, commissioning, training, and after-sales support. A global spare parts network ensures minimal downtime, while predictive maintenance and digital monitoring enhance reliability. Sustainability and energy efficiency are prioritized with high-efficiency motors, low-waste adhesive handling, and environmentally friendly materials.

Tenghong fosters a corporate culture of innovation, quality, and customer satisfaction. Its teamwork-driven approach combines R&D, production, and service teams to deliver complete B2B solutions. Footwear pasting machines are engineered to optimize production efficiency, maintain product quality, and support flexible multi-style manufacturing. Clients benefit from reduced labor costs, consistent output, and scalable operations, positioning Tenghong as a trusted partner for global footwear factories seeking advanced, reliable, and cost-effective machinery.