The pneumatic sole press machine is a pivotal innovation in the footwear manufacturing industry, designed to streamline the sole attachment process while ensuring unmatched precision and efficiency. Guangdong Tenghong Machinery Technology Co., Ltd., established in 2000 in Dongguan, China, has been at the forefront of developing such advanced machinery. With over 150 industry experts and a commitment to quality, the company specializes in creating solutions that cater to the evolving needs of global footwear brands.

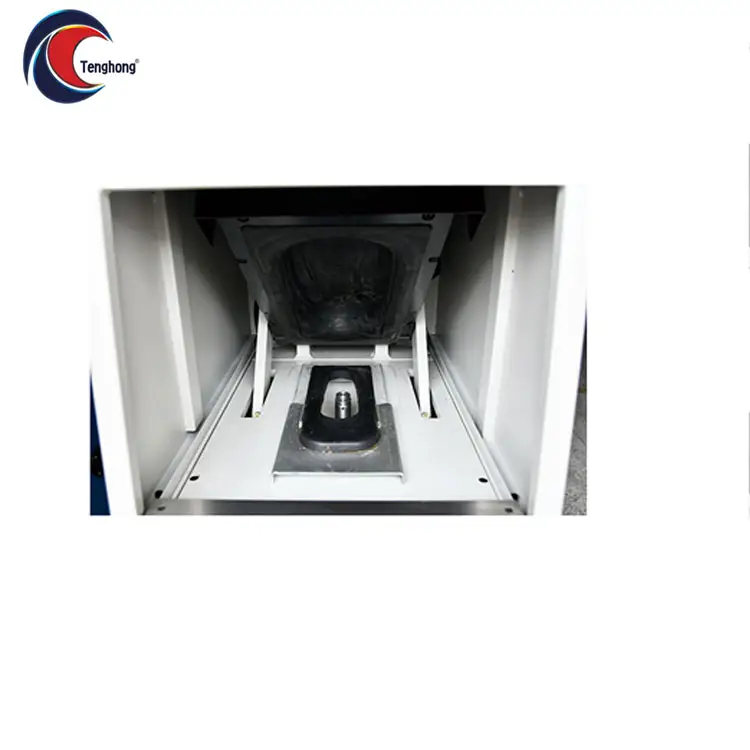

This pneumatic sole press machine is widely used in the production of athletic shoes, casual footwear, and safety boots. Its dual-pressure system ensures that the sole is first evenly packed and then firmly pressed onto the upper, resulting in a strong and lasting bond. The machine's adaptability allows it to handle various shoe sizes and materials, making it ideal for manufacturers producing diverse product lines. Additionally, its automated features reduce the need for manual intervention, significantly cutting down labor costs and production time.

One of the standout features of this machine is its ability to operate in both automatic and manual modes. In automatic mode, the machine works seamlessly once the shoe is positioned correctly, while the manual mode offers greater control for custom designs. This flexibility makes it suitable for both mass production and specialized orders. The machine also includes safety features such as automatic shutdown when hands are detected in the work area, ensuring operator safety.

Guangdong Tenghong Machinery leverages its extensive expertise and ISO9001:2008 certification to deliver products that meet the highest standards of quality and reliability. The company provides comprehensive support services, including pre-sale consultations, custom machine configurations, installation, training, and after-sales maintenance. This end-to-end approach ensures that clients receive not just a machine but a complete solution tailored to their production goals.

In summary, the pneumatic sole press machine is an essential tool for footwear manufacturers seeking to enhance their production processes. Its precision, efficiency, and versatility make it a valuable investment for businesses aiming to stay competitive in the global market.