Guangdong Tenghong Machinery Technology Co., Ltd. has many years of professional experience in footwear machinery R&D and manufacturing. It is dedicated to providing footwear manufacturers and buyers with high-efficiency, intelligent, and stable production equipment. The PU sole attaching machine combines intelligent PLC control with an advanced hydraulic system to ensure tight and uniform bonding between soles and uppers, widely applied in both sports and casual shoe production.

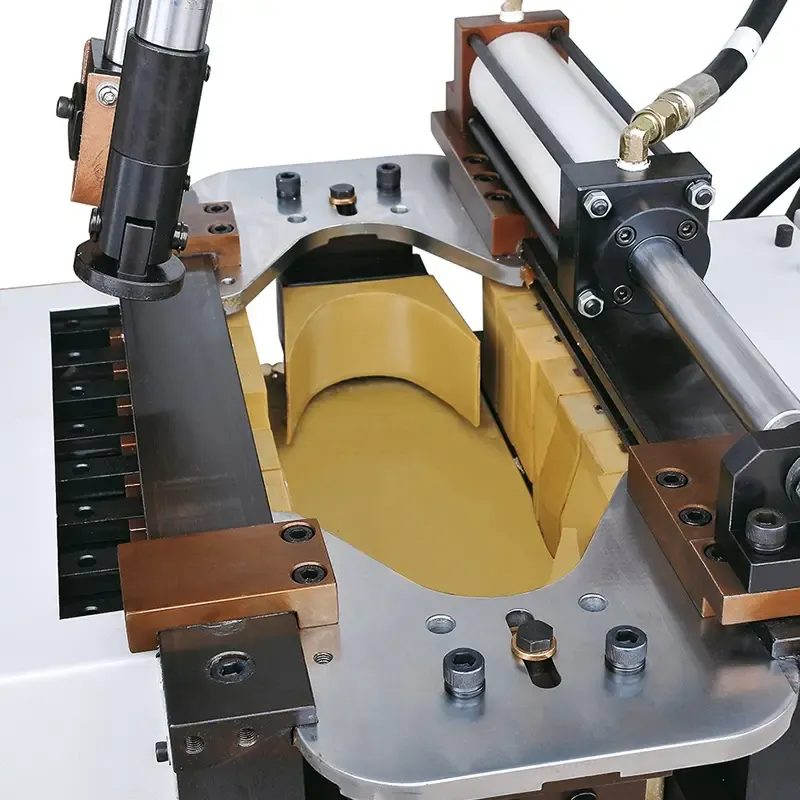

The machine features a compact design and easy maintenance, with 16 pressing blocks supporting multi-point and multi-station synchronous or independent pressing. Its stable and efficient hydraulic system delivers strong bonding power, adaptable to various shoe last widths and sole thicknesses, aligning perfectly with modern automated footwear production lines. Tenghong Machinery leads footwear manufacturing innovation with cutting-edge technology and excellent after-sales service.