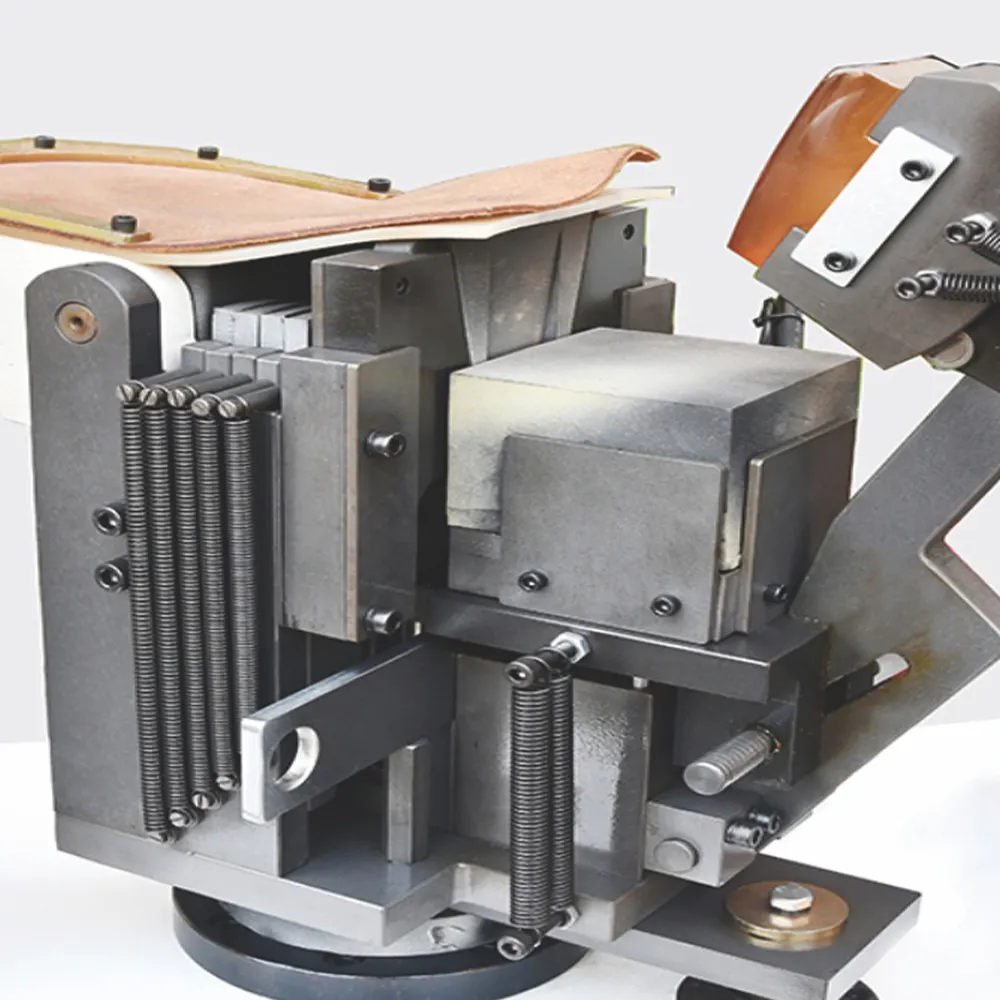

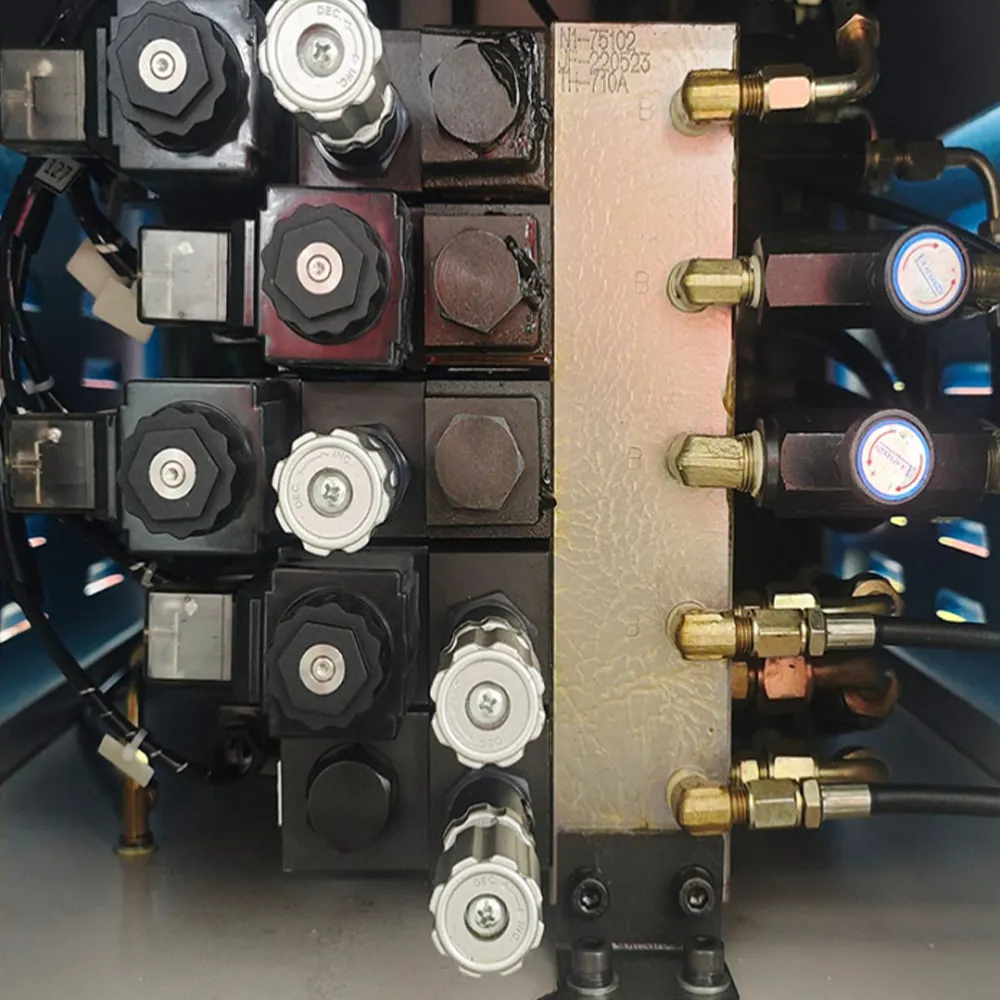

গুয়াংডং টেংহং মেশিনারি টেকনোলজি কোং লিমিটেড হল পেশাদার হাই-টেক এন্টারপ্রাইজ যা জুতা মেশিনারির গবেষণা ও উত্পাদনে বিশেষীকরণ করে। এটি জুতা প্রস্তুতকারক এবং সরবরাহকারীদের কাছে স্থিতিশীল পারফরম্যান্স এবং উচ্চ দক্ষতাসম্পন্ন উত্পাদন সরঞ্জাম সরবরাহে নিবদ্ধ। PU সোল আট্যাচিং মেশিনটি একটি উচ্চ-দক্ষতাসম্পন্ন হাইড্রোলিক সিস্টেম এবং নির্ভরযোগ্য স্বয়ংক্রিয় নিয়ন্ত্রণের সাহায্যে সোল এবং আপারগুলিকে সঠিকভাবে বন্ড করে, মানের পাশাপাশি বৃহৎ পরিমাণ উত্পাদনের চাহিদা পূরণ করে।

সংক্ষিপ্ত এবং রক্ষণাবেক্ষণে সহজ, এই মেশিনটি একাধিক লাস্ট প্রস্থ এবং সোল উচ্চতা সমর্থন করে, বিভিন্ন ধরনের জুতার বাজার চাহিদা পূরণ করে। এর উত্কৃষ্ট বন্ডিং পারফরম্যান্স এবং উচ্চ আউটপুট কারখানাগুলিকে খরচ নিয়ন্ত্রণ করতে এবং প্রতিযোগিতামূলকতা বাড়াতে সাহায্য করে। নিরবিচ্ছিন্ন নবায়ন এবং ব্যাপক পোস্ট-সেলস পরিষেবা দিয়ে তেংহং মেশিনারি জুতা উত্পাদন সরঞ্জামের বুদ্ধিমান আপগ্রেডের নেতৃত্ব দেয়।