The role of hydraulic sole presses in modern footwear manufacturing is fundamental for accurate sole pressing and die-cutting. Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 in Dongguan’s shoe manufacturing heartland, Houjie Town, combines deep industry expertise and advanced technology development. With a professional team of over 150 members specializing in research, production, and customer service, Tenghong produces a wide range of shoe machinery, including toe lasting machines, heavy-duty walled sole attaching machines, hydraulic heel seat lasting machines, and visual trajectory servo control systems, servicing clients globally.

The hydraulic swing arm clicking press die cutting machine exemplifies Tenghong’s dedication to technological excellence. It harnesses patented hydraulic pressure with a swinging arm design that guarantees rapid, stable cutting performance while minimizing noise and oil temperature. Even workers without extensive experience can operate the machine safely, thanks to the intuitive design and manual switch controls.

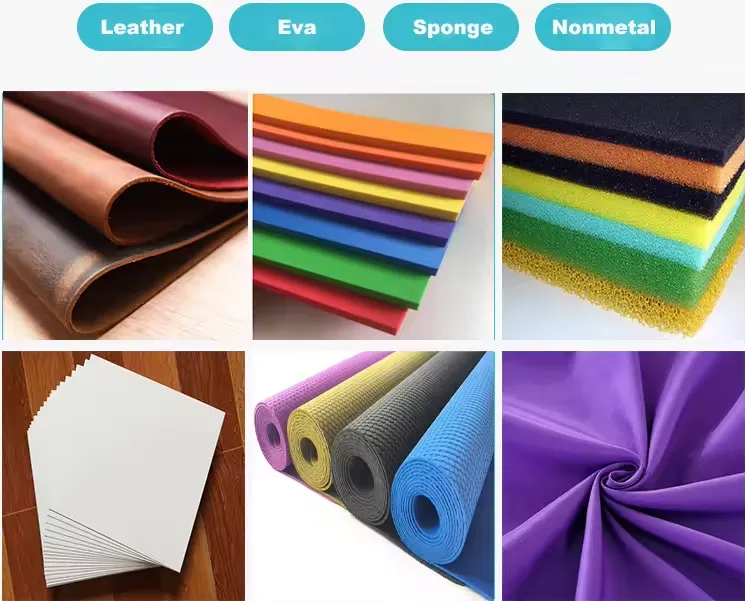

Versatility is a hallmark of this hydraulic sole press—it handles various non-metal products used in footwear, leather accessories, gloves, headwear, decorative flowers, arts & crafts, plastic packaging, garment accessories, and automotive supplies. This machine’s durability, coupled with easy cleaning and low breakdown rates, translates into higher uptime and improved production efficiency.

Tenghong’s commitment to quality management under ISO9001:2008 and continuous learning from international technology ensures that each hydraulic sole press is optimized for performance and value. Customers receive comprehensive support including turnkey plant planning, installation, commissioning, and prompt after-sales maintenance. This partnership approach empowers shoe manufacturers and related industry users to deliver superior products with reliable, energy-conscious equipment.