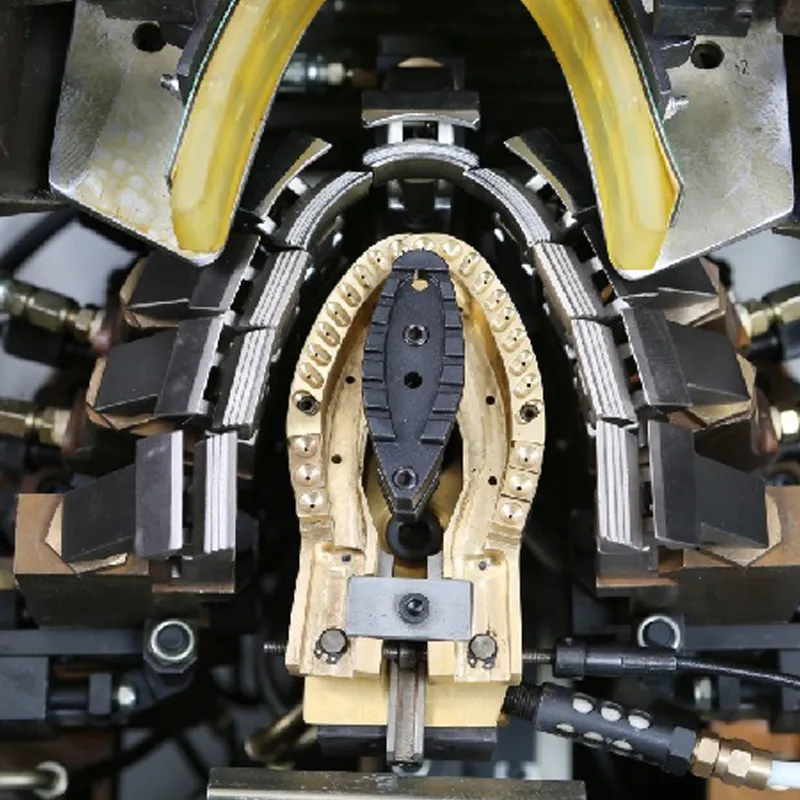

Guangdong Tenghong Machinery Technology Co., Ltd. was established in 2000 in Dongguan, China. The company specializes in high-tech shoe machinery manufacturing and offers comprehensive R&D, manufacturing, and customer support. With over 150 professionals, Tenghong produces intelligent leather shoe toe lasting machines equipped with hydraulic and PLC control systems. Their products feature durable construction, easy-to-maintain designs, and adaptable settings, meeting diverse production needs. Tenghong continues to innovate and lead in global footwear equipment manufacturing, adhering to strict quality standards.