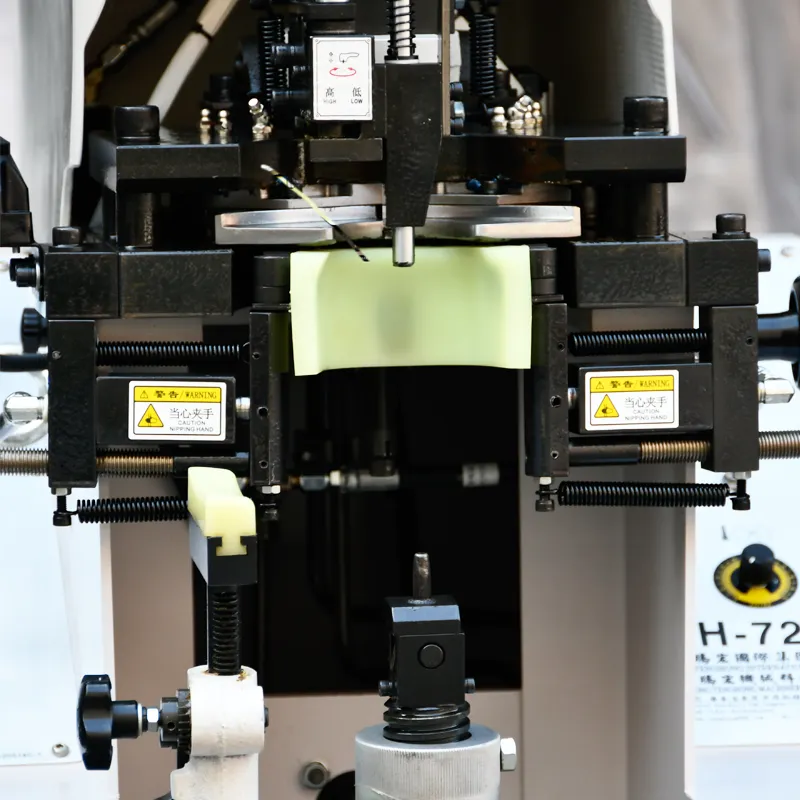

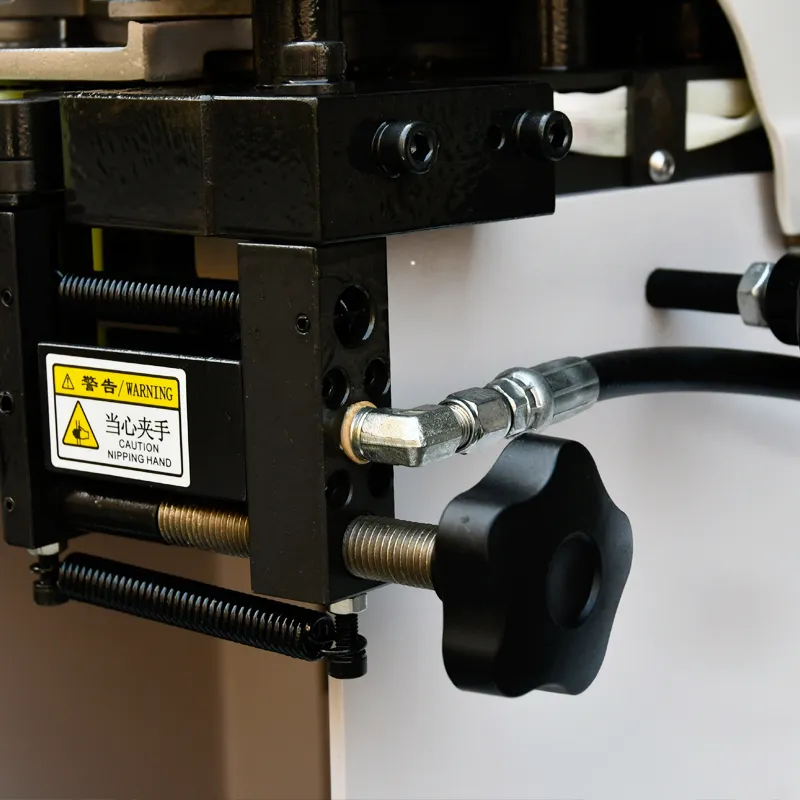

Founded in 2000 and located in Dongguan, Guangdong Province, Guangdong Tenghong Machinery Technology Co., Ltd. specializes in manufacturing high-tech shoe-making machinery. With a team of over 150 industry experts, the company develops and produces advanced footwear production equipment. As a quality shoe lasting machine supplier, Tenghong offers intelligent PU sole attaching machines featuring PLC control and hydraulic systems to ensure durable and uniform sole bonding.

The machines are compact, easy to maintain, and cover a wide range of shoe last widths, lengths, and sole thicknesses, meeting modern footwear production demands. Complete with excellent after-sales service, Tenghong supports factories in upgrading production efficiency and product quality through continuous innovation and customer-focused solutions.