In the evolving footwear industry, rotary shoe sole machines are crucial for ensuring strong, durable, and aesthetically pleasing sole attachment. Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 and located in Dongguan's major footwear manufacturing hub Houjie Town, employs over 150 experts who specialize in shoe machinery innovation and manufacturing. Their comprehensive product portfolio ranges from toe lasting machines to heavy-duty sole attaching and hydraulic heel lasting machines, catering to diverse global clients.

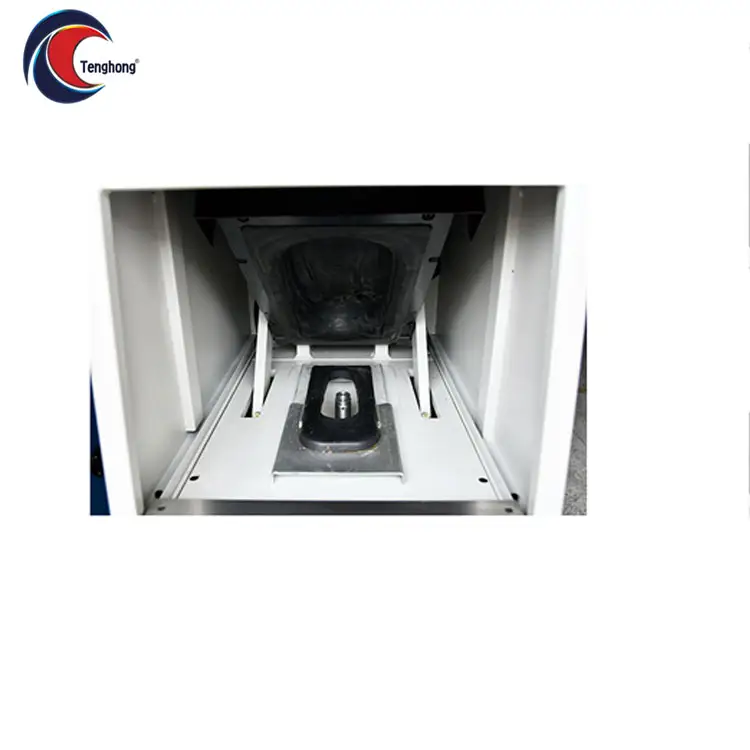

The TH-586A pneumatic rotary shoe sole machine elevates sole pressing by integrating safety-focused adjustable shoe height and dual-operation modes. Operators can seamlessly switch between manual start for beginners and automated start for experienced personnel, ensuring optimal safety and efficiency. This machine’s dual air-tight cylinders alternate action to apply two distinct pressures—first consolidating the sole and then pressing for superior adhesion between the shoe upper and the sole, which minimizes defects and enhances product longevity.

Designed with modern shoe lines in mind, it handles various footwear styles such as athletic and casual shoes featuring large, slick soles. The adjustable compression time and consistent air pressure provide precise welding control, reducing waste and operational errors. Its compact design allows easy integration into existing assembly lines, boosting plant productivity.

Guangdong Tenghong Machinery pairs its technological excellence with comprehensive service including pre-sale consultation, turnkey project planning, installation, commissioning, and responsive after-sales support. This holistic approach ensures customers maximize their production capacities and maintain high standards in footwear manufacturing globally.