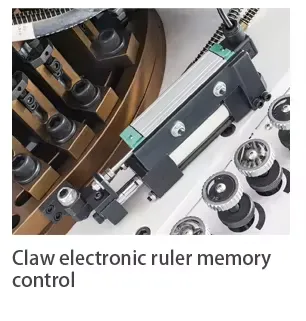

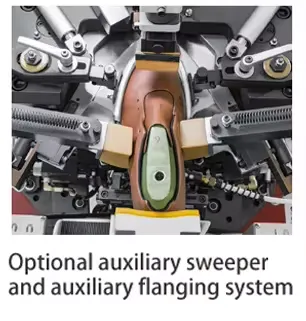

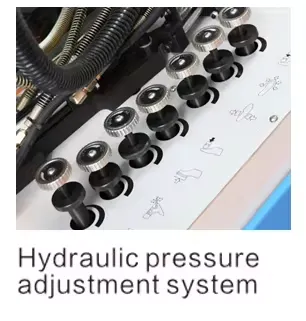

Combining stable hydraulic oil pressure with a programmable PLC control system, this toe lasting machine provides operational reliability and user-friendly management. Its touch-screen interface enables quick input and memory locking of lasting parameters like stroke and duration. The 7-pincer setup leverages a patented double-track disc and secondary displacement structure for faster setup and flexible shoe pattern adaptation. The middle pincer allows side-to-side movement of 15 degrees, and the fifth pincer’s rotation capability improves inner waist lasting quality. Operators can switch between automatic and manual pincer controls to precisely balance vamp tension during lasting. Adjustable two-stage pressure indenters ensure lasting accuracy while protecting delicate upper materials. Optional auxiliary features such as sweep knives and holding arms offer additional control over lasting quality. The machine outputs up to 2000 pairs in an 8-hour period, ideal for modern, automated footwear production lines focusing on accuracy and productivity.

Founded in 2000 and headquartered in Dongguan’s famed footwear manufacturing area, Guangdong Tenghong Machinery Technology Co., Ltd. specializes in the research, development, and production of high-tech shoe machinery equipment. The company’s product suite includes toe lasting machines, heavy-duty sole attaching machines, hydraulic heel seat lasting machines, and advanced servo-controlled side and heel lasting equipment. It boasts a seasoned team of over 150 professionals dedicated to innovation, quality assurance, and customer support. Operating under ISO9001 standards, Tenghong actively adopts global cutting-edge technology and offers full-spectrum services including pre-sale consultation, manufacturing, onsite installation, training, and after-sales maintenance. These efforts help footwear factories worldwide achieve intelligent production upgrading and cost-effective manufacturing.