The sole press machine price reflects the technology, build quality, and operational capacity. Guangdong Tenghong Machinery Technology Co., LTD., located in Dongguan’s renowned shoe manufacturing area, specializes in high-tech and mass-produced shoe and leather machinery. Founded in 2000, the company has developed a wide range of equipment including the TH-710A hydraulic sole pressing machine that merges durability with advanced automation.

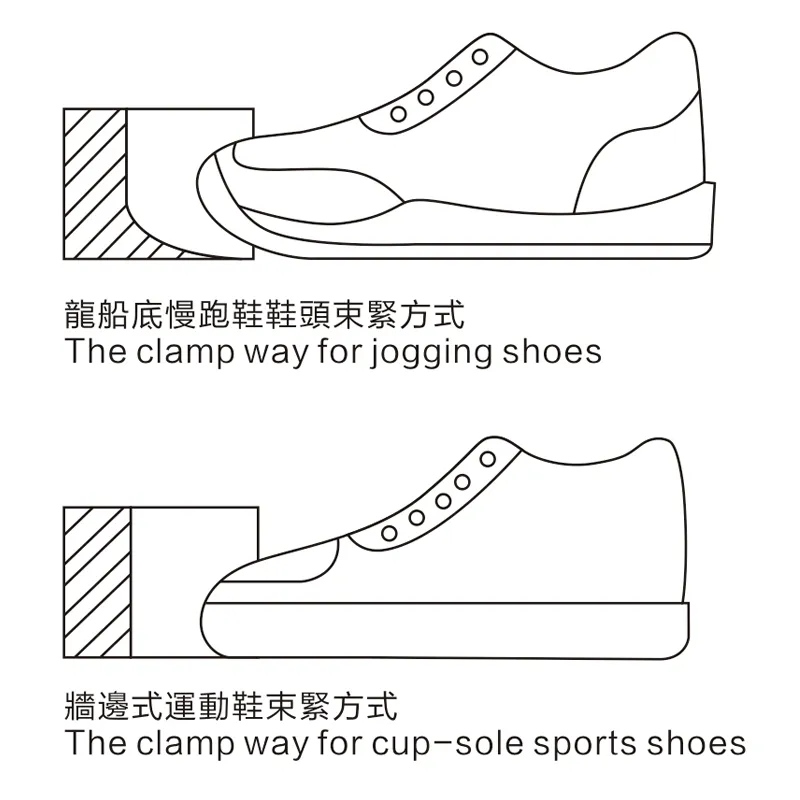

The TH-710A applies even, strong pressure with its oil-powered hydraulic system, ensuring solid adhesion for shoes including boat shoes and casual footwear with wrapped edges or toes. Its ability to perform bottom, edge, and front/back pressing independently or simultaneously makes it adaptable to different production processes. The machine’s adjustable pressing blocks and pressure settings provide precise control over sole bonding quality. This facilitates consistent output and reduces the risk of defects.

Tenghong invests substantially in research, development, and customer service. Their machines comply with ISO9001:2008 quality management standards. Comprehensive pre-sale consultancy, onsite installation, debugging, and after-sales maintenance services ensure clients receive maximum support and value. For shoe manufacturers, the competitive price combined with performance efficiencies makes the TH-710A a strong contender in automated sole pressing equipment.

By selecting this sole press machine, businesses gain labor savings through automation and improve production throughput without compromising quality. This is critical in meeting large order volumes and demanding industry standards while controlling operational costs.