The shoe sole press machine is vital to quality footwear production, ensuring that soles bond securely to uppers through consistent pressure application. Guangdong Tenghong Machinery Technology Co., LTD., located in Dongguan’s renowned shoe manufacturing hub, has been producing and innovating advanced shoe machinery since 2000. The company offers a comprehensive line of machines including the pneumatic TH-586A sole attaching machine, which is engineered to meet modern factory demands for efficiency and quality.

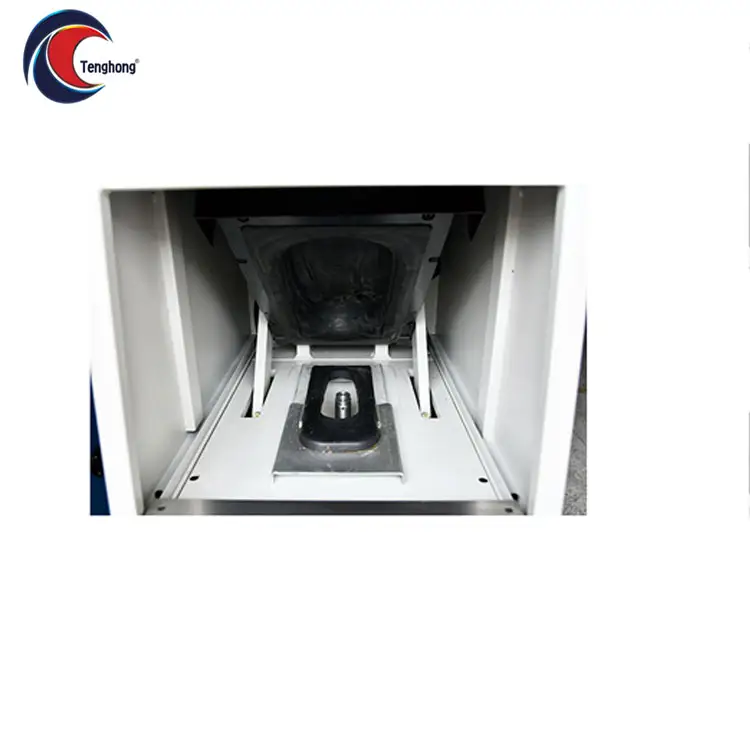

The TH-586A uses electrical components with pneumatic control and features auto/manual mode switching. Operators place pre-glued shoes in the correct position, after which the cover closes automatically when hands leave the work area, initiating the pressing cycle. The machine automatically applies a two-stage pressure process: first packing the sole, then applying additional pressure for enhanced bonding. The air pressure regulation valve and adjustable compression time provide adaptability to different sole materials and thicknesses.

Tenghong Machinery’s commitment to ISO9001:2008 quality standards, combined with its team of experienced engineers and industry professionals, ensures that customers receive durable, high-performing machines tailored to their needs. Tenghong supports clients with pre-sale consulting, plant layout planning, on-site installation, debugging, and after-sales technical assistance to maximize production uptime.

The pneumatic shoe sole press machine is widely adopted in manufacturing sports shoes, leisure shoes, and other soles requiring smooth and effective adhesion. By automating pressing operations and providing adaptable pressure settings, this machine helps shoe producers reduce labor costs, improve product consistency, and increase output.