The TH-715A shoe sole pressing machine exemplifies the intersection of hydraulic technology and footwear manufacturing expertise. Guangdong Tenghong Machinery Technology Co., LTD., founded in 2000 and based in Dongguan’s shoe industry hub, supplies advanced shoe making machinery designed to boost productivity and product quality. Their line includes the TH-715A, a heavy-duty machine engineered to satisfy demanding production environments.

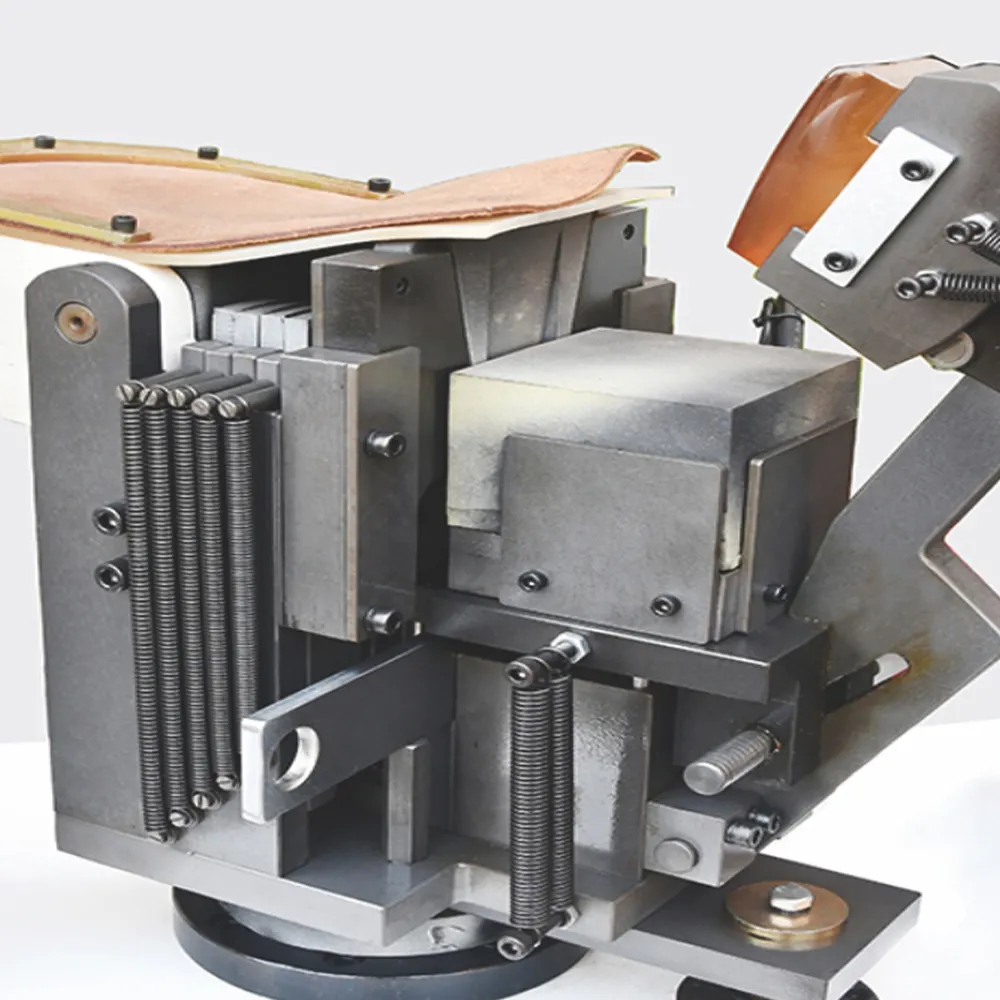

This machine’s hydraulic system applies steady pressure through eight adjustable side blocks, enabling precise adherence of soles on shoes including dragon boat soles and casual footwear with wrapped edges. The flexible pressing modes allow for customization according to shoe specifications, making it efficient for various styles and sizes. Its 2.2 kW pump and oil-based pressure system ensure robust power with adjustable parameters for detailed control.

Tenghong’s commitment to international quality standards like ISO9001:2008 ensures that their machines meet global expectations. Their skilled R&D and technical teams provide customers with tailored plant design, installation services, comprehensive after-sales support, and expert maintenance guidance. This holistic approach enables clients to minimize downtime and maximize return on investment.

The TH-715A supports manufacturers targeting high output rates without compromising on sole bonding quality. Its versatility and durability reduce manual labor, improve consistency, and accelerate production cycles. For B2B buyers seeking cost-effective, high-performance shoe sole pressing machinery, the TH-715A represents a reliable solution optimized for modern footwear production lines.