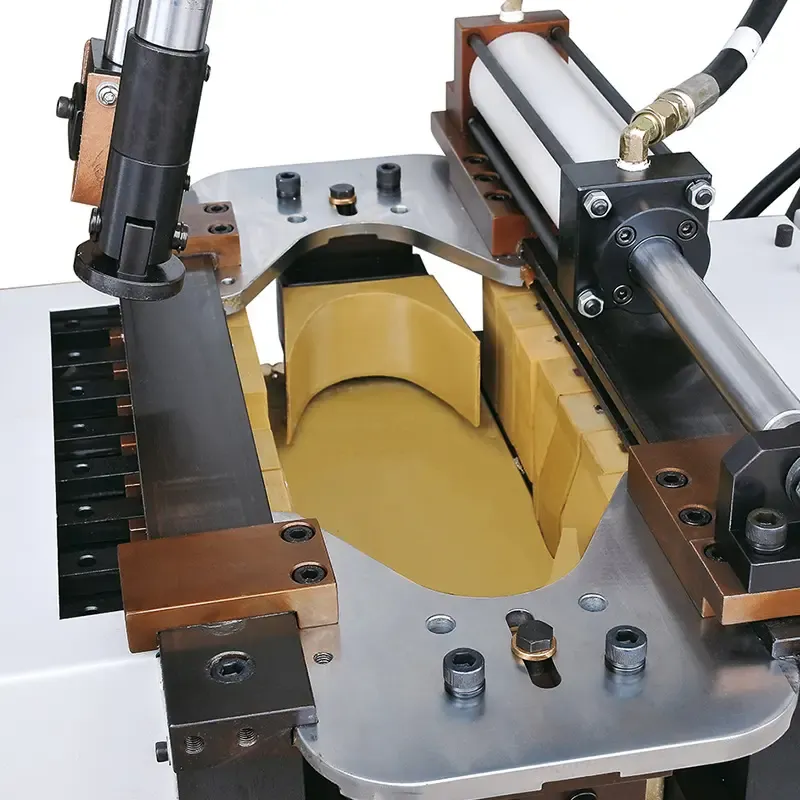

The TH-710D high efficiency sole pressing machine represents a significant advancement in footwear manufacturing technology, offering unparalleled performance and reliability. This sophisticated equipment is specifically designed for attaching walled soles to various types of footwear, including specialized boat shoes, sports shoes, and casual footwear. The machine's advanced PLC control system allows for precise parameter settings and consistent operation, ensuring perfect sole attachment every time. With its ability to handle last widths up to 140mm and lengths ranging from 130mm to 400mm, it accommodates most common shoe sizes and styles.

Guangdong Tenghong Machinery Technology Co., Ltd. has established itself as a leading manufacturer of footwear production equipment since its founding in 2000. Located in Houjie Town, Dongguan—a renowned center for shoe manufacturing—the company leverages its strategic location and industry expertise to develop innovative solutions for modern footwear production. With a team of over 150 experienced professionals, Tenghong maintains a strong focus on research and development, continuously improving their high efficiency sole pressing machines to meet evolving industry needs.

The application scenarios for this high efficiency sole pressing machine are extensive and varied. It excels in production environments requiring consistent quality and high output, particularly for footwear with specialized sole attachment requirements. The machine's programmable settings make it ideal for manufacturers producing multiple shoe models, as it allows for quick changeovers between different production specifications. Its robust construction and reliable performance also make it suitable for high-volume manufacturing facilities operating around the clock.

Tenghong's company advantages extend beyond product manufacturing to encompass comprehensive customer support services. The company provides expert guidance on equipment selection, factory layout planning, and production optimization. Their commitment to ISO9001:2008 quality standards ensures that every high efficiency sole pressing machine meets rigorous performance criteria. The combination of technical expertise, quality manufacturing, and excellent customer service makes Tenghong a preferred partner for footwear manufacturers worldwide.