Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000 in Houjie, Dongguan, is a leading manufacturer of high-tech customized shoe machines and complete footwear production solutions. With over twenty years of expertise, Tenghong specializes in designing and producing advanced machinery that meets the dynamic needs of modern footwear factories.

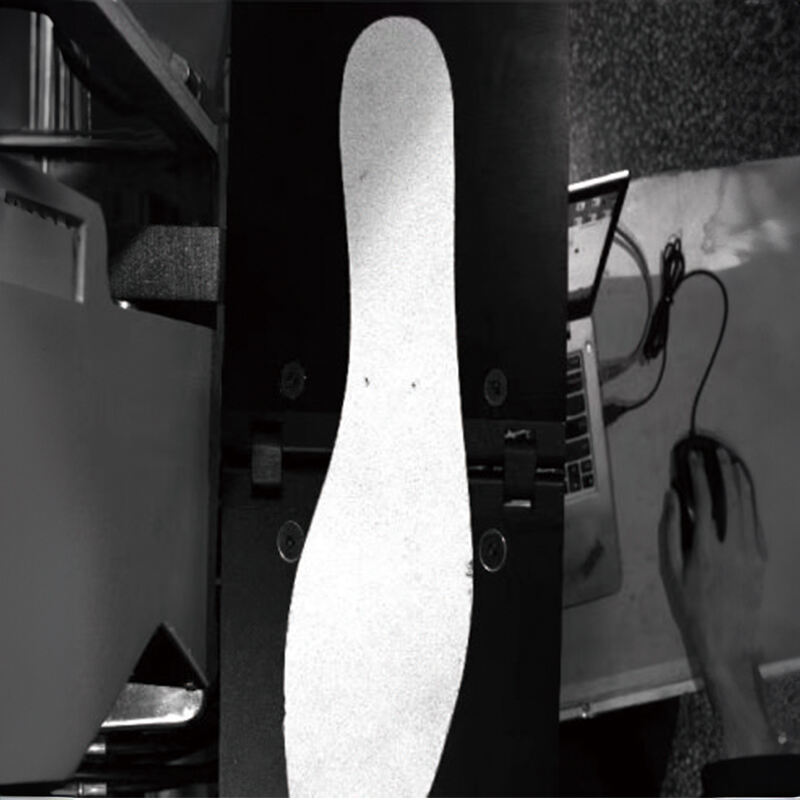

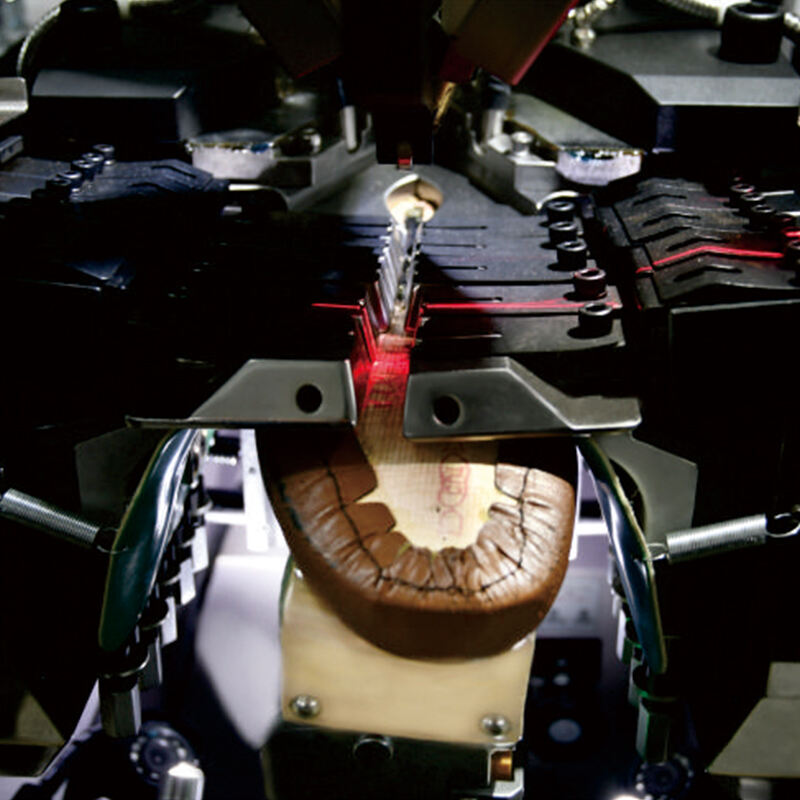

The company’s customized shoe machines offer CNC-controlled cutting, robotic stitching, automated gluing, multi-density sole injection, and finishing operations that ensure consistent quality, precision, and efficiency. Machine vision systems continuously monitor every component and assembly step, while IIoT-enabled monitoring provides real-time production analytics, predictive maintenance alerts, and process optimization. Modular designs allow rapid adaptation to different shoe styles, sizes, and materials, supporting a wide range of commercial, professional, and specialty footwear production.

Tenghong is ISO9001-certified and CE-compliant, guaranteeing adherence to international quality and safety standards. A team of over 150 engineers, including R&D and production experts, continuously develops innovative solutions to improve automation, efficiency, and precision. These technologies minimize labor dependency, reduce material waste, and optimize energy consumption while maintaining multi-shift, high-volume production consistency.

The company also provides comprehensive services covering pre-sale planning, factory layout design, equipment installation, commissioning, operator training, and ongoing maintenance. Remote technical support and fast spare parts delivery ensure long-term operational reliability. Tenghong’s corporate culture emphasizes innovation, teamwork, and customer satisfaction, guided by the philosophy of “mutual benefit and ideal achievement.” This approach ensures factories receive efficient, flexible, and high-quality customized shoe machines that enhance production capacity, maintain consistent product standards, and maximize ROI. Tenghong’s solutions are recognized worldwide, particularly in Southeast Asia, Europe, and other key markets, helping factories meet diverse consumer demands while improving efficiency and reducing operational costs.