As the footwear industry moves towards intelligent, high-quality manufacturing, the womens shoe molding machine becomes crucial in enhancing upper shaping quality and production efficiency. Guangdong Tenghong Machinery Technology Co., Ltd., founded in 2000, has a strong R&D and production team of over 150 experts, specializing in shoe machinery development. The company offers a comprehensive product range including toe lasting machines, heavy-duty sole attaching machines, hydraulic heel lasting machines, and intelligent vision control systems, widely used by footwear manufacturers worldwide.

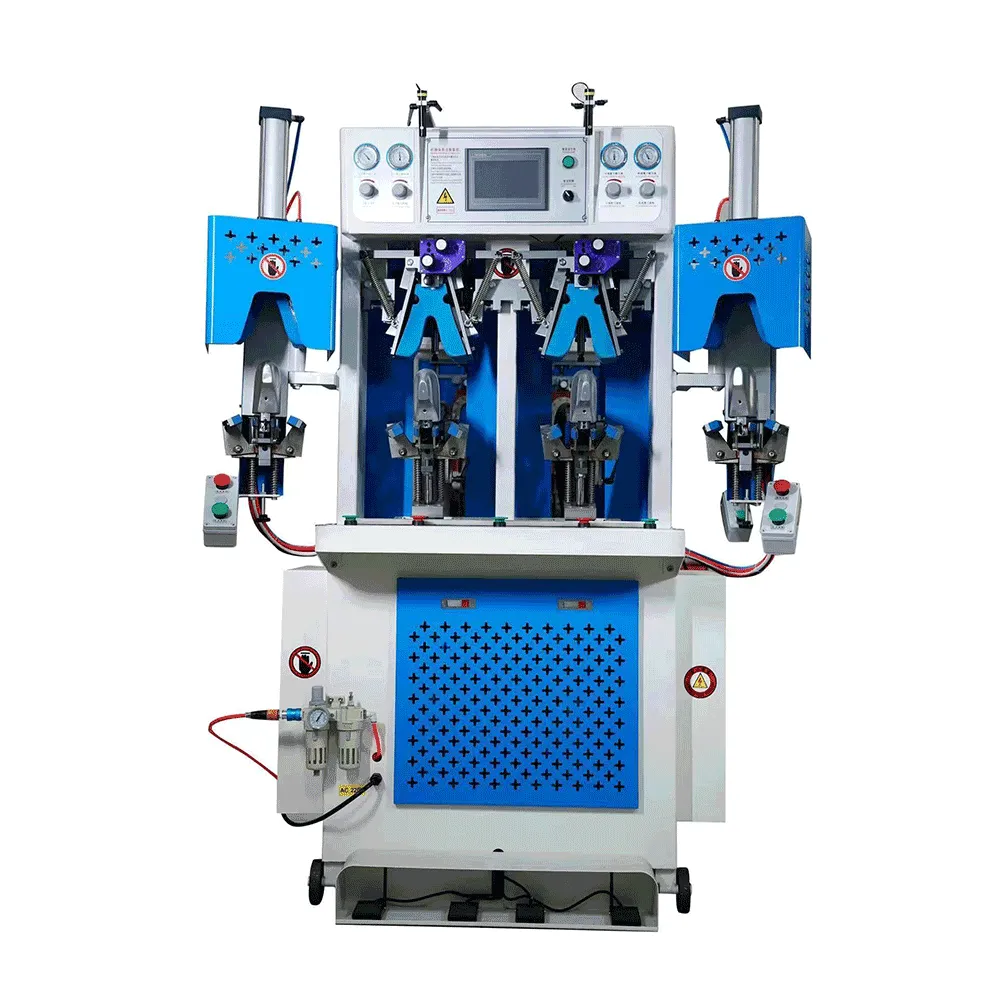

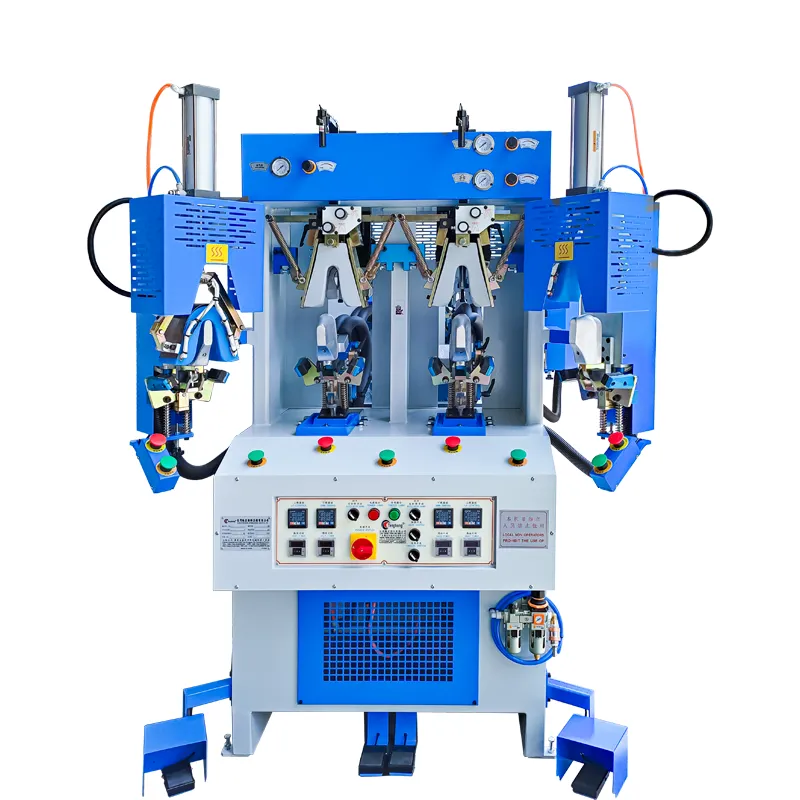

The TH-319 women’s shoe molding machine features dual hot and cold stations, allowing simultaneous uniform heating and rapid cooling of the shoe upper. It uses environmentally friendly refrigeration technology with a minimum temperature of -30℃ to maintain product stability. The adjustable Teflon tightening device ensures consistent pressure across various upper materials, avoiding wrinkles and deformation during molding. The tiltable mold mechanism simplifies mold loading and unloading, enhancing safety and efficiency.

The streamlined airflow, precise temperature control, and ergonomic design reduce labor intensity and increase production capacity. Tenghong Machinery upholds a commitment to innovation and customer service, providing pre-sale consulting, installation, training, and after-sales support to ensure customers achieve intelligent manufacturing excellence.