Hydraulic shoe sole pressing machines are vital in the modern footwear industry as they combine precision control with powerful performance to guarantee high-quality sole attachment. Guangdong Tenghong Machinery Technology Co., LTD, founded in 2000 and located in Dongguan’s renowned shoe manufacturing region, specializes in producing advanced shoe making machines including heavy-duty hydraulic sole attaching machines. Over two decades of industry experience have enabled Tenghong to develop equipment meeting stringent quality standards such as ISO9001:2008 certification ensuring reliability and performance.

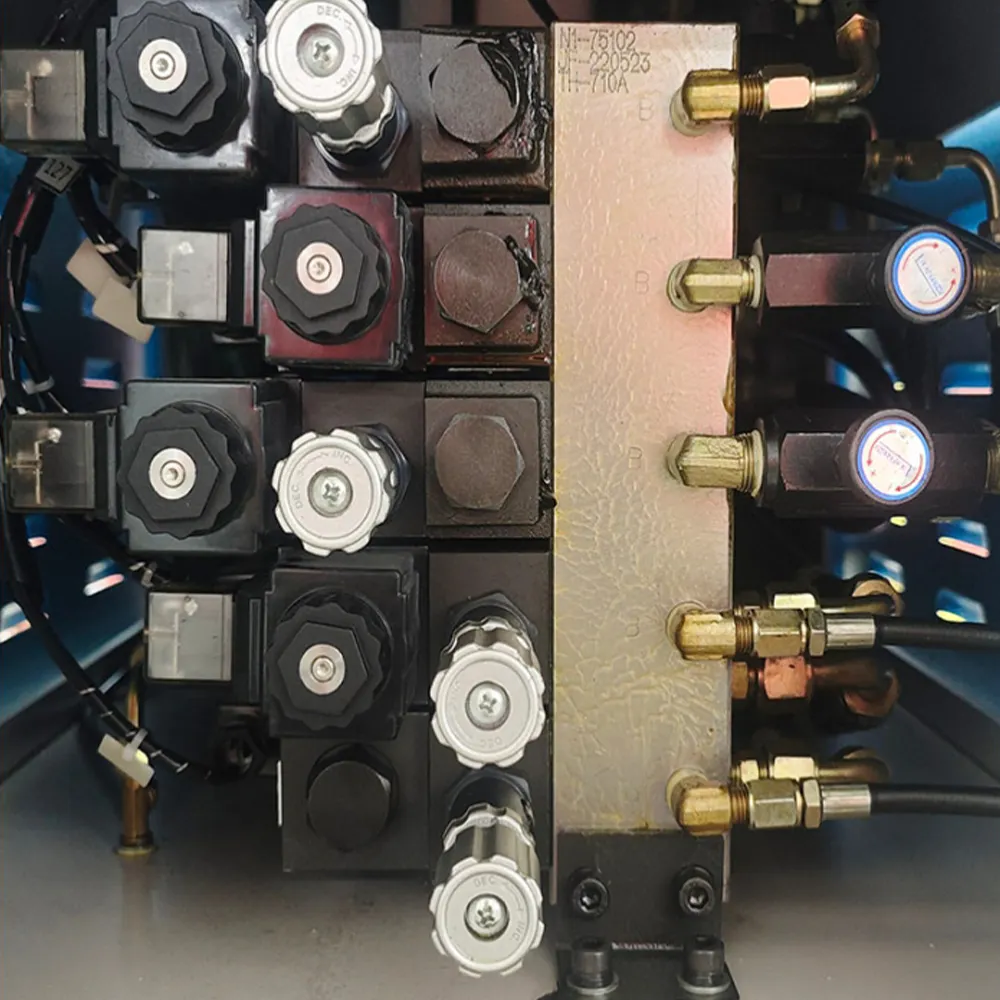

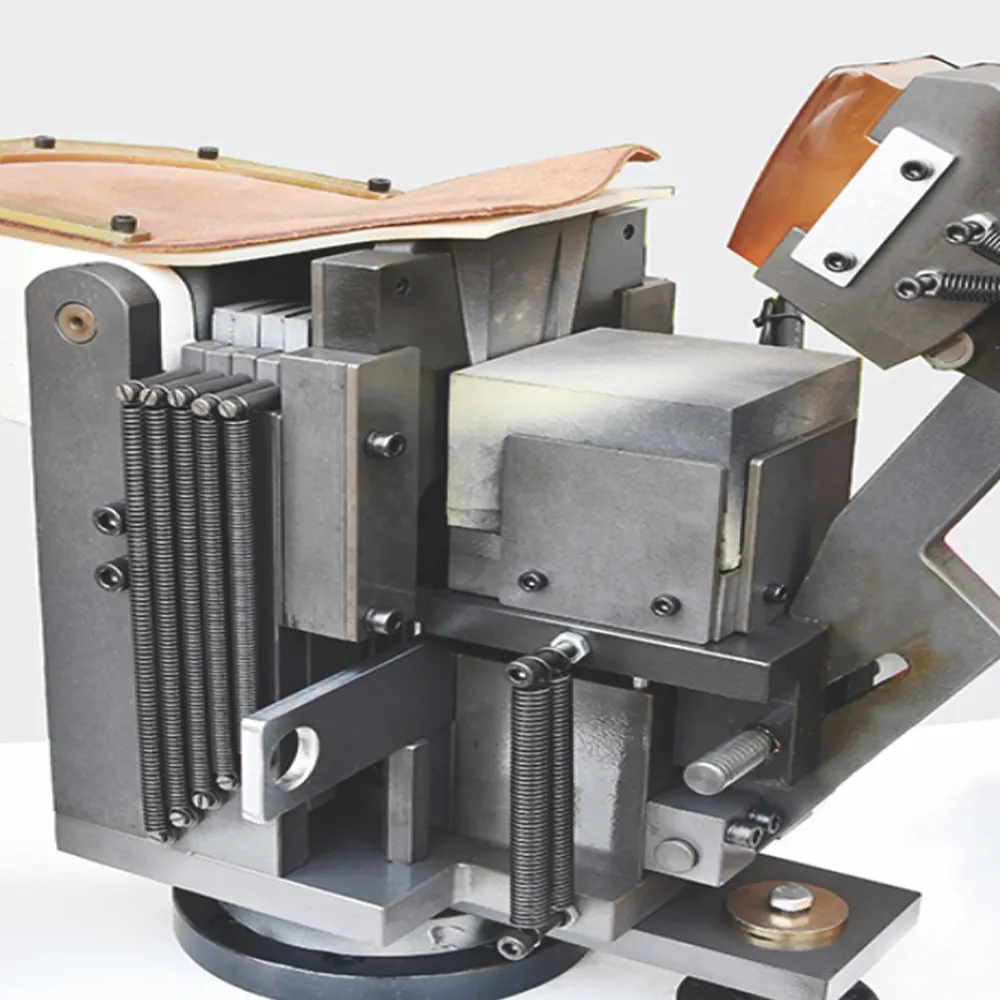

The hydraulic sole press from Tenghong is designed to meet the needs of manufacturers producing wall-type wrapped soles, dragon boat soles, and other complex sole configurations. It caters to shoes with last widths up to 140 millimeters, lengths from 130 to 400 millimeters, and sole edges of up to 80 millimeters in height. The machine features a powerful 2.2-kilowatt pump providing hydraulic pressure up to 40 kilograms per cubic meter, facilitating even pressing across the shoe sole surface. The ability to adjust pressure for each individual pressing action allows optimal bonding without damaging shoe components.

This machine finds widespread usage in industries manufacturing casual footwear, sports shoes, and specialty boat shoes where sole durability and quality finishing are critical. Tenghong’s dedication to product innovation and comprehensive customer support including pre-sale consultation, installation, and technical guidance elevate their machines as reliable choices for shoe factories looking to enhance productivity and quality control. The company’s advanced hydraulic shoe sole pressing machines save labor costs, improve pressing uniformity, and increase output, making them essential assets in competitive shoe manufacturing environments.